- HOME

- HOME

- Technical Information

- Bellows glossary

- About usage environment

About usage environment

Even identically shaped bellows will vary in performance if they are used with different shapes.

Terminology related to the environment that will affect a bellows performance is shown.

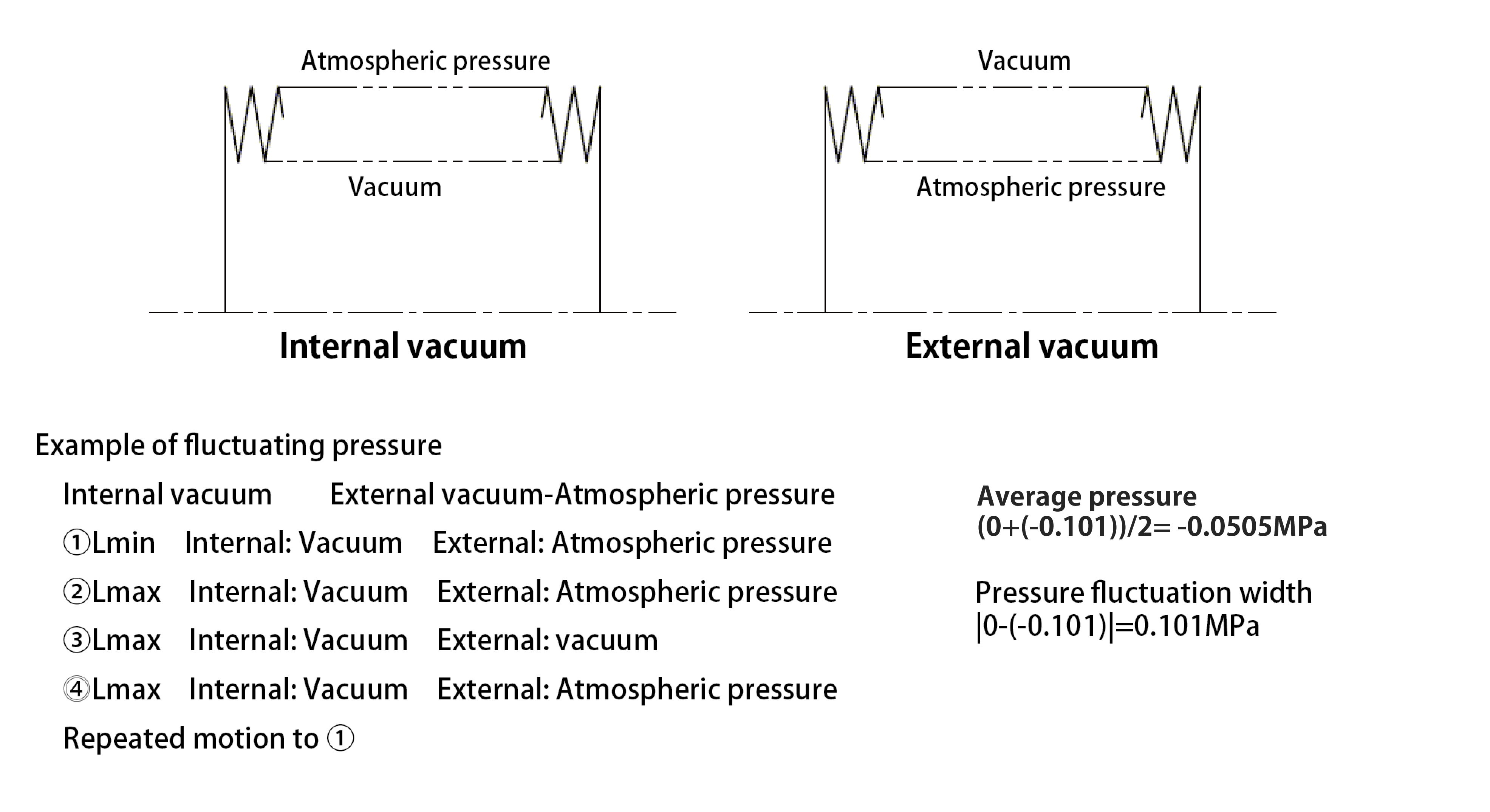

Pressure types

※左右にフリックしてご覧いただけます。

| Name | Description |

|---|---|

| Internal vacuum | Conditions under which the inside of bellows is vacuum and the outside is atmospheric pressure |

| External vacuum | Conditions under which the inside of bellows is atmospheric pressure and the outside is vacuum |

| Internal pressure | State in which a pressure higher than the outside of bellows is applied to the inside, or its pressure |

| External pressure | State in which a pressure higher than the inside of bellows is applied to the outside, or its pressure |

| Equal pressure | State in which equal pressure is applied to the inside and outside of bellows * Normally, both the inside and outside are atmospheric pressure in this state * This state is frequently used during maintenance |

| Fluctuating pressure | Pressure changes in operating cycle, which greatly affects life performance depending on condition * There are cases when it occurs at the time of stop bellows or due to volume changes caused by expansion/contraction, etc. |

| Average pressure | Average pressure in the case where fluctuating pressures are applied; assuming that the external pressure is negative and the internal pressure is positive: (maximum pressure + minimum pressure)/2 |

| Pressure fluctuation width | fluctuating pressures are applied; assuming that the external pressure is negative and the internal pressure is positive: |maximum pressure - minimum pressure| |

Usage environment (other than pressure)

※左右にフリックしてご覧いただけます。

| Name | Description |

|---|---|

| Working temperature | Temperature at which the bellows is used, the characteristics of which are dependent on the materials used. With increasing temperature, the life performance deteriorates. SUS304(L), SUS316(L) --- 500°C or less AM350 equivalent --- 450°C or less Hastelloy®C-22 --- 800°C or less |

| Baking | Treatment by raising temperature, which is commonly performed in the vacuum industry with a heater in order to remove moisture and impurities in vessels. The commonly-used temperature is about 100 to 250°C. |

| Working fluid | Gas, liquid, or vapor filled inside or outside the bellows. Corrosive fluid is taken into consideration when bellows material is selected. |

Glossary of bellows terms

Product Information List

Inquiry

For document requests and inquiries,

Please contact us using the email form below or by phone.