- HOME

- HOME

- Product Information

- Vacuum Valve

- Round gate valve "MARINA" Exhaust valve etc...

Round gate valve "MARINA" Exhaust valve etc...

Over the last three decades, the semiconductor market has evolved without being bound by Moore's Law, and miniaturization has made rapid progress from Microscale to nanoscale.

Manufacturing equipment has also been miniaturized through continuous technological development, and the vacuum gate valves mounted on it are also required to constantly improve their performance.

We are working on high functionality every day to meet the growing market demand.

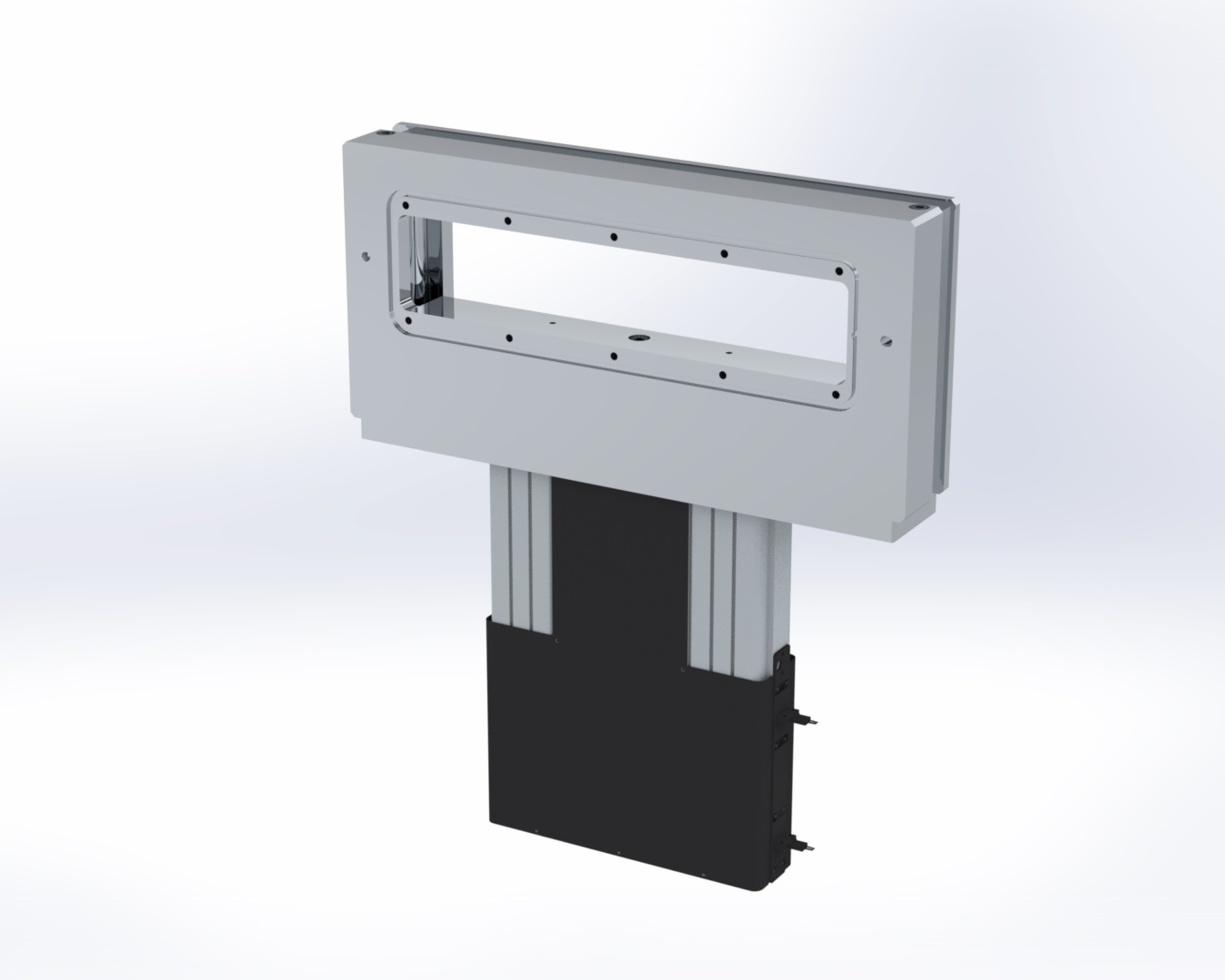

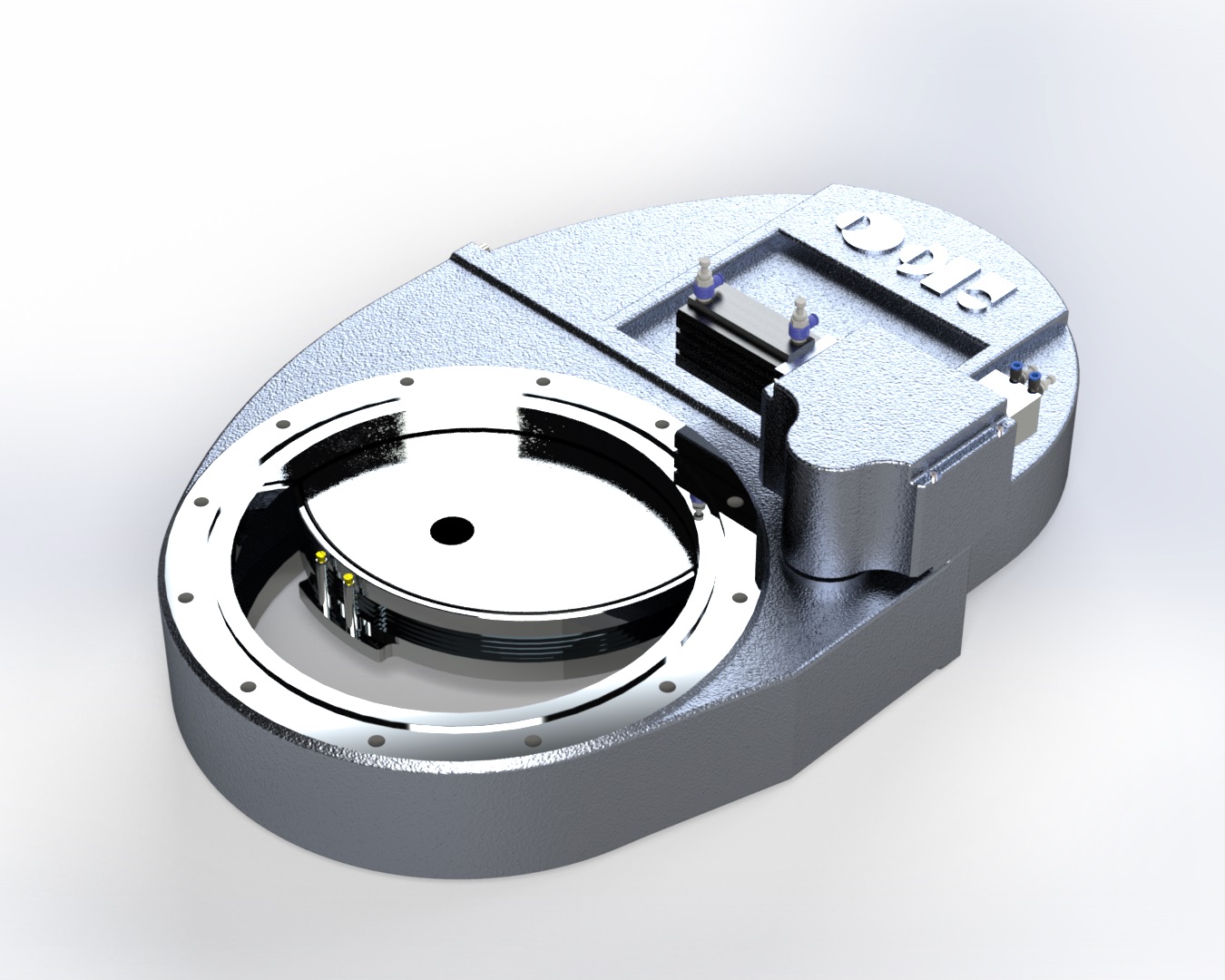

Vacuum gate valve MARINA Exhaust valve

|

・Main valve for exhaust |

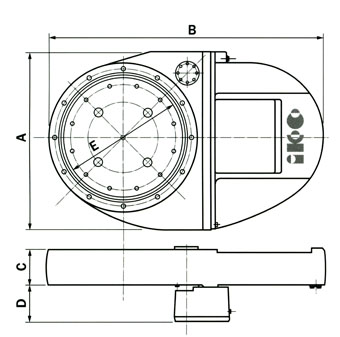

Specifications

Leak rate |

Body:1 × 10-10[Pa・m3/s] Gate:5 × 10-10[Pa・m3/s](Negative pressure) |

|---|---|

Temperature |

Body :120 [℃ ] Actuator :60 [℃ ] |

| Open/Close moving time | 3.0 ~ 5.0 [s] |

Material |

Body:AC4C-T6 Bellows:SUS316L(Pressure cancellation) Gate:A5052 Sealing:FKM |

| operating Air pressure | 0.45 ~ 0.60 [MPa] |

| Service life | 1M[Cycles] |

| Option | Spec without Pressure cancellation |

| Bore | Type | A | B | C | D | E |

| 250 | M-250J(S)-2(3) | 460 | 655 | 100 | 134.5 | 250 |

| 320 | M-320J(S)-2(3) | 555 | 790 | 120 | 129.5 | 320 |

| 400 | M-400J(S)-2(3) | 630 | 944 | 135 | 129 | 400 |

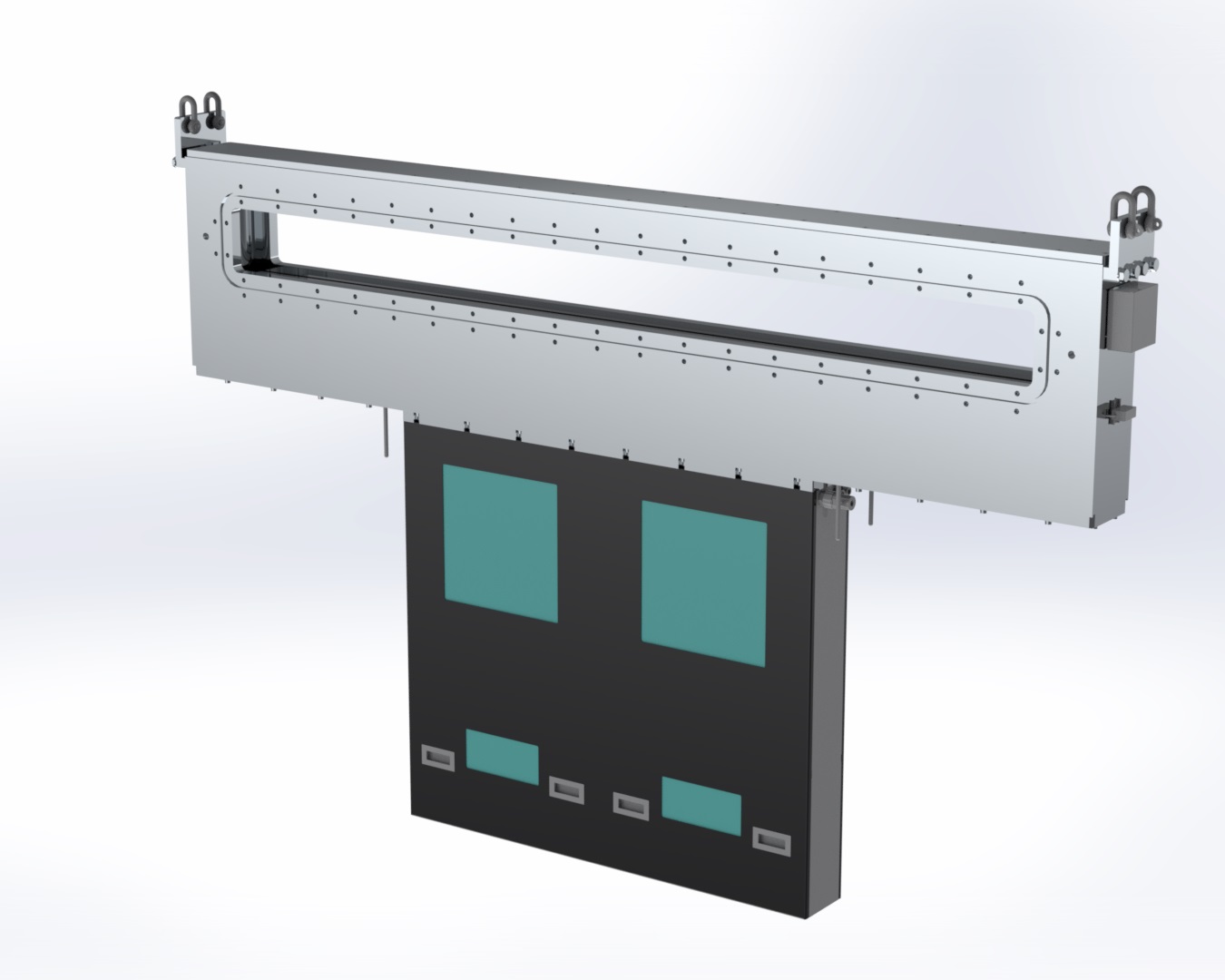

Vacuum gate valve CDV

|

|

Specifications

| Leak rate | Gate:5 x 10-10[Pa・m3/s](Equal/Positive pressure) |

|---|---|

Temperature |

Body/Gate :120 [℃ ] Actuator :60 [℃ ] |

| Open/Close moving time | 2.5~ 5.0 [s] |

Material |

Gate:A5052 Sealing:FKM |

| Operating Air pressure | 0.45 ~ 0.60 [MPa] |

| Service life | 1M[Cycles] |

Custom Design

Please let us know your requirements.

We will consider your request individually.

- We want to reduce particles to accommodate miniaturization.

- We want to reduce the release of adherent particles by reducing vibration.

- We want to reduce equipment downtime during maintenance.

If you have specific requirements, please let us know the details of your specifications.

We will be happy to provide you with force calculations and design proposals that meet your required specifications.

KOSLARZE

A gate valve developed and developed with "non-sliding" as a design concept.----------------------------------------------------------I want to use it as a sluice valve for semiconductor manufacturing equipment.

Please select the following case

GARIVA

It is a gate valve that is synonymous with our company, which specializes in large opening sizes.----------------------------------------------------------I want to use it as a sluice valve for flat panel display manufacturing equipment.

Please select the following case

MARINA

----------------------------------------------------------I want to use it as an exhaust valve.

Please select the following case

FQA

MARINA Main valve for exhaust

In addition to square gate valves (for partitioning of substrate transfer), main valves for exhaust are also available.

MARINA type (valve mechanism is based on the same concept as GARIVA) and LINK type are available upon request.

MARINA Equipped with pressure canceling mechanism

This is a product based on the same concept as the large vacuum gate valve GARIVA. The pressure cancel mechanism inside the valve eliminates the load of atmospheric pressure against the seal and allows the valve to withstand reverse pressure with less force. The bellows used in the pressure cancellation mechanism is our own product.

MARINA Compatible with 500A (developed product)

The standard specification is for a maximum bore size of 400 mm. We can accommodate up to 500 mm upon customer request.

CDV Atmospheric gate for load lock chamber

This is a gate valve to be installed at the substrate inlet of the load lock chamber. It is not a valve installed between each chamber, so it does not use a valve box or bellows.

CDV For ultra-large FPD / OLED devices( ~ G10.5)

FPD production equipment is becoming larger and larger, and the maximum substrate inlet size can exceed 3000 mm. CDV provides simple and stable sealing even in large openings by using a cylinder inside the valve to press on multiple points.

CDV High reliability due to simple mechanism

The CDV is installed at the board inlet.

The CDV is installed at the substrate inlet and requires less sealing force than a vacuum gate valve, resulting in a simple, lightweight, and highly reliable product with fewer parts.

Related Information

Columns

解決事例

Technical Information

Please take a look at the technical information on gate valves.

Inquiry

For document requests and inquiries,

Please contact us using the email form below or by phone.