Search by Purpose

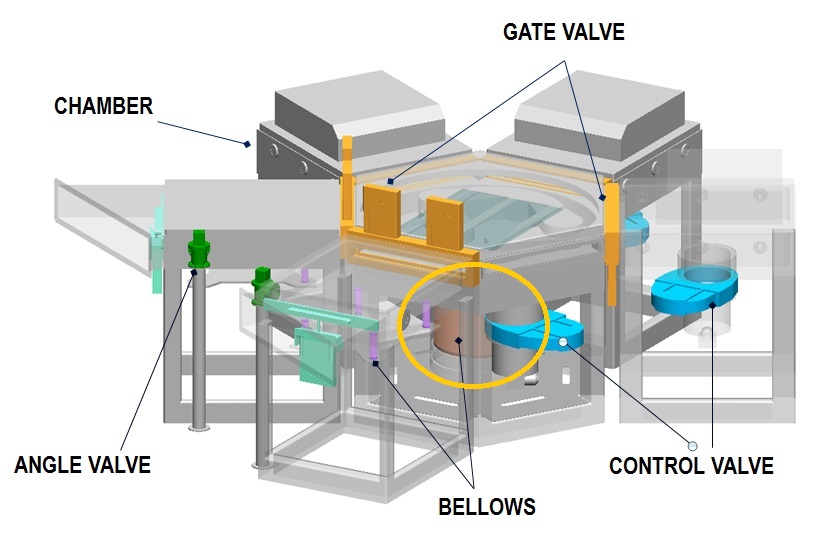

I need bellows for semiconductor wafer transfer mechanism

We offer welded bellows for semiconductor wafer transfer mechanism.

We can meet your requirements (specifications) such as stroke length, vertical transfer speed, etc.

Products that solve problems

Welded Bellows

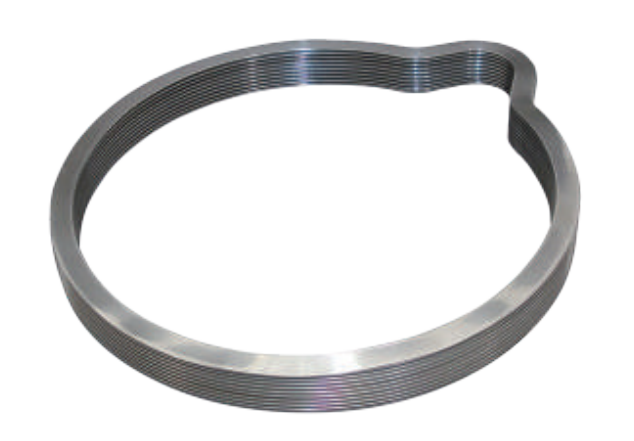

Welded bellows are metal bellows manufactured by joining thin-walled metal plates on precision discs by welding the inner and outer diameters alternately.

Metal Bellows

IRIE KOKEN's basic technology lies in the manufacture of metal bellows. We focus especially on the field of precision bellows, which require high performance and high reliability, and have been widely used in the vacuum field.

What is a bellows?

In the field of vacuum handling, a bellows is generally a cylindrical object made of metal with folds to give it elasticity, airtightness, and springiness.

Formed Bellows

The roll forming method of mechanical forming and the bulge forming method using hydraulic pressure are widely used in general. We manufacture bellows using our original hydraulic forming method.

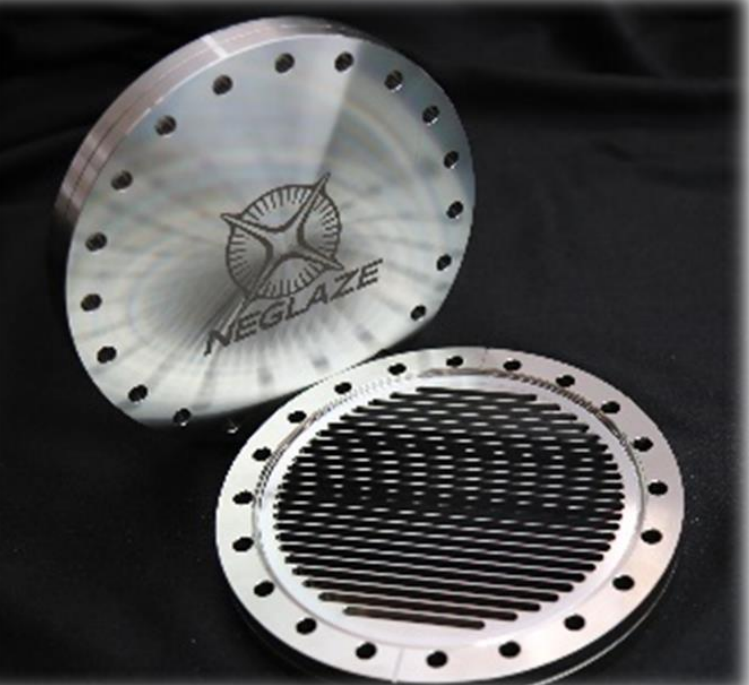

I want to create an ultra-high vacuum

Please consider the NEGLAZE oxygen-free Pd/Ti-deposited ICF zero-length NEG pump.

The NEG (Non-Evaporable Getter) is a vacuum pump capable of generating an ultra-high vacuum by exhausting using the getter action. Unlike getter pumps, which generate vacuum by heating and sublimation, NEGs adsorb gas molecules such as hydrogen on or inside the membrane by heating and cooling the membrane formed on the inside of the vacuum component. Generally, it is used in combination with a turbo molecular pump.

I need titanium bellows or welded fabrication

Titanium is superior to stainless steel in terms of light weight, corrosion resistance, biocompatibility, and high-temperature strength.

We have the technology to design and manufacture bellows with performance equivalent to stainless steel.

We can provide either Type 1 or Type 2 bellows, taking into consideration the use environment, required characteristics, and marketability of the material.

Please consult with us.

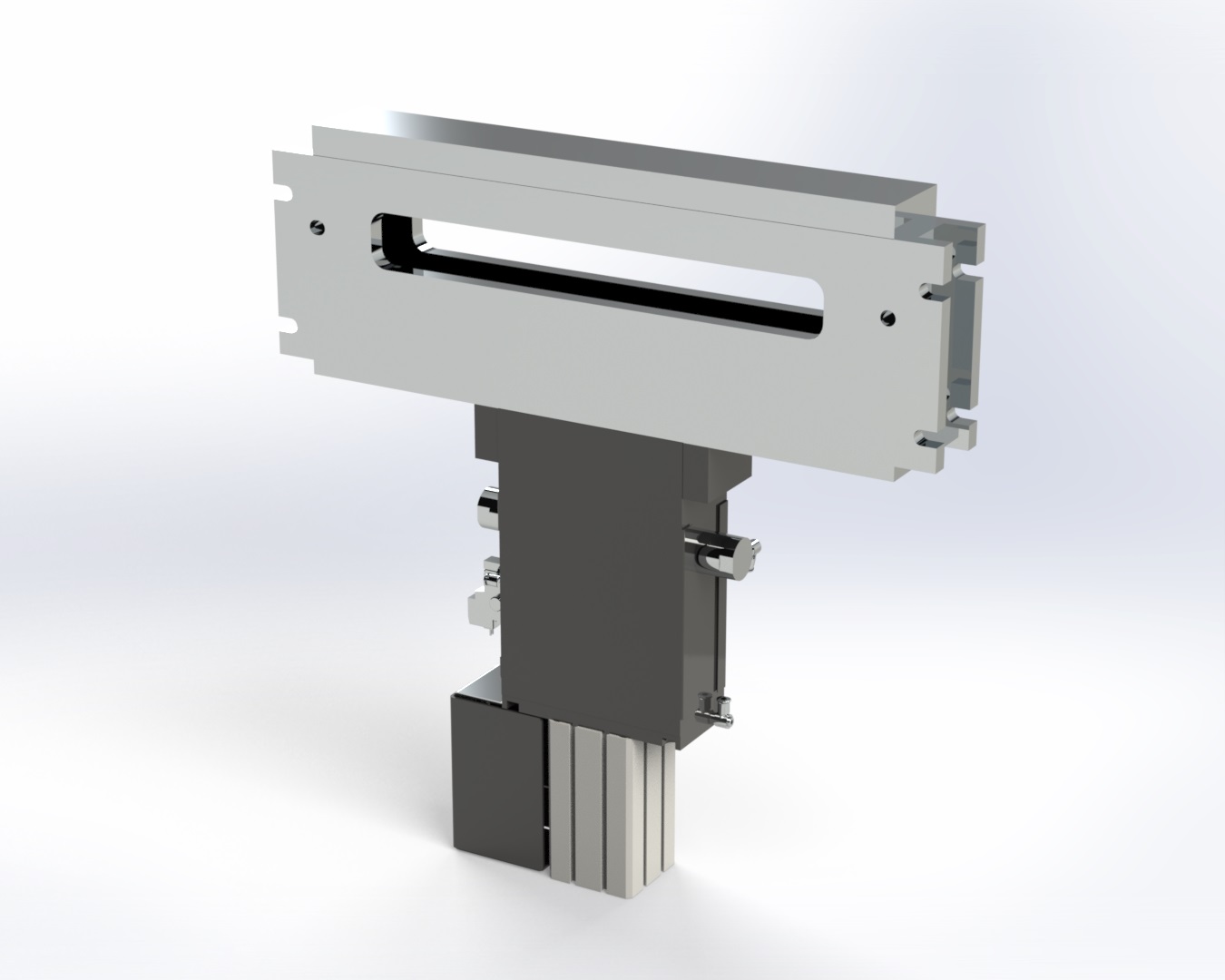

I want rectangular bellows.

Rectangular bellows are bellows with square or rectangular openings as their basic shape.

They are used to absorb mounting errors at the joints between chambers and at the joints between chambers and gate valves.

IRIE KOKEN offers two types of rectangular bellows, folded bellows and welded bellows, to meet various needs, from absorption of installation errors to expansion and contraction displacement.

I want bellows of any shape

Free-form bellows are bellows manufactured with an aperture in accordance with the customer's requirements.

They are manufactured with an appropriate aperture shape in the available space when the space for bellows cannot be secured with round, rectangular, or elliptical bellows due to equipment or piping design reasons.

IRIE KOKEN's free-form bellows are available for various needs, from absorption of mounting errors to expansion and contraction displacement.

I need a vacuum gate valve that can seal both sides depending on maintenance

Consider the KOSLARZE'S both sided seal, direction-switching type, which is a gate valve with additional functions to the Normal type.

By switching the seal direction to the transfer chamber side, the vacuum is maintained except for the process chamber, which is open to the atmosphere, thus allowing the equipment to continue operating during maintenance of the process chamber. The O-ring for sealing the valve plate on the process chamber side can be easily replaced.

Inquiry

For document requests and inquiries,

Please contact us using the email form below or by phone.