- HOME

- HOME

- Product Information

- Metal Bellows

- Welded Bellows

Welded Bellows

Welded bellows are metal bellows manufactured by connecting thin metal plates on precision discs while alternately welding the inner and outer diameters.

The bellows can be displaced axially, perpendicularly and angularly, with the internal and external pressures separated by welding.

- A compact and large amount of expansion and contraction can be obtained, and a long-life design is possible.

- Elasticity and spring characteristics can be set by changing the inner and outer diameter dimensions and plate thickness.

- The end fitting (Y type) can be welded by the customer.

- Excellent pressure resistance.

Standard Welded Bellows

We have a lineup of single bellows and welded bellows with conflat flanges on both ends.

All of them can be used under the following pressure, temperature, and specified life conditions.

Standard Specifications

Pressure Condition |

(Internal) Vacuum (External) Atmospheric pressure |

|---|---|

| Temperature Conditions | Normal temperature (max 250℃ during baking) |

| Operating Conditions | Axial displacement only |

| Amount Of Leak | 1×10-9 Pa・m3/s or less |

Material |

(Bellows) Equivalent to SUS316L/AM350 (Bellows single item only) (Flange) SUS304L |

Specified Life |

(Single bellows) 1, 10, 1,000,000 times (With conflat flange) 10,000 times |

* Only SUS316L is available for the 10,000 times single bellows specification.

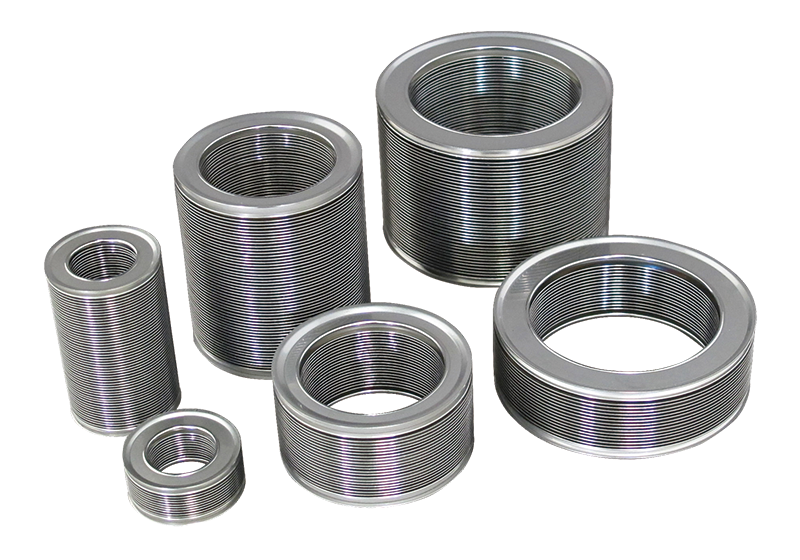

Single Bellows

Standard Welded bellows only.

--------------------------------------------------------------------------------------

When metal fittings are welded by the customer.

When the customer supplies us

with metal fittings and we weld the fittings ourselves.

--------------------------------------------------------------------------------------

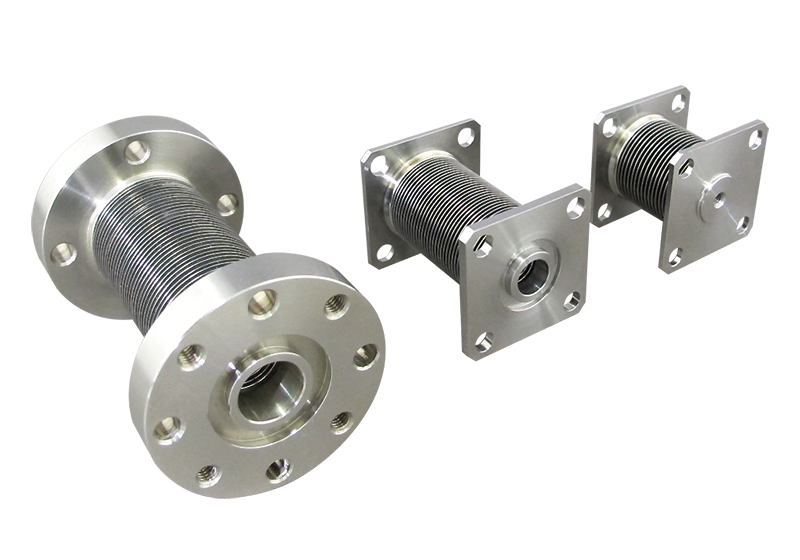

It can be used in the adove casesBellows With Conflat Flange

Welded bellows with CF flanges on both ends.

--------------------------------------------------------------------------------------------

【You can select the type of CF flange】

1) Both ends fixed

2) Fixed - rotation

Individually Designed Product

Even if standard products do not meet the specifications

We will consider them individually.

- I want a more compact design

- I want to allow displacement in directions other than the axial direction.

- I want to use it for pressurization as well.

If you have a specific request such as, please let us know the details of your specifications.

Please feel free to contact us as we will propose the optimal design for various uses.

FAQ

What materials should be selected?

Bellows materials are selected according to the environment in which they will be used, taking into consideration corrosion resistance, magnetism, and heat resistance.If there are no specific conditions to consider, we will consider materials that are more compact and less expensive within the specifications.

How should bellows be sized if the shaft passes inside the bellows?

Contact between the bellows and the shaft prevents it from performing as it should.Normally a clearance of 2 mm per side is sufficient, but if the length is long enough to buckle, a large clearance is required.Regardless of the shaft inside, if there is concern about interference with structures around the bellows, please contact us for the appropriate clearance to take this into account.

Is it safe to use bellows in dusty environments?

Contact Bellows can be prematurely damaged by foreign bodies.Note that the horizontal position is significantly affected. Welded bellows have partial contact between the bellows folds, so dust emission is not zero, but does not affect service life.Formed bellows are more effective when the required displacement is small, as there are fewer parts in contact.

Related Information

Column

Solution Example

Technical Information

Please take a look at the technical information on bellows.

Inquiry

For document requests and inquiries,

Please contact us using the email form below or by phone.