- HOME

- HOME

- Technical Information

- What is a valve?

What is a valve?

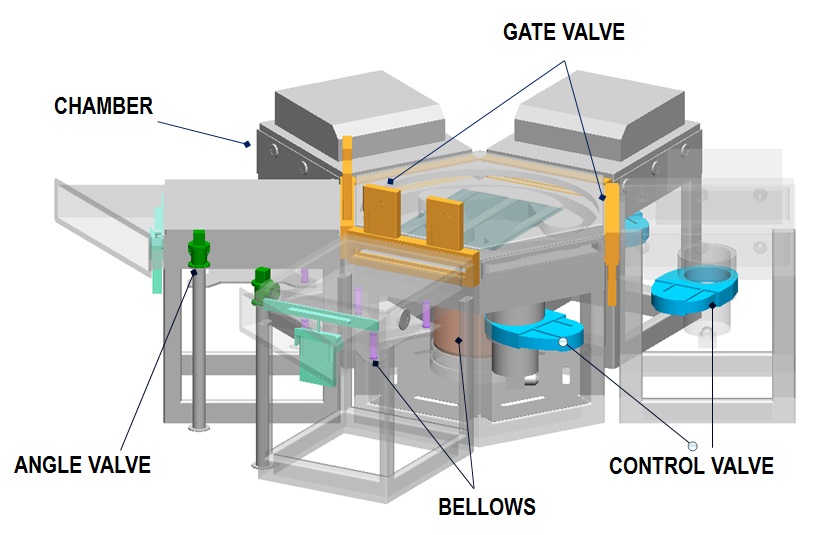

Vacuum valves are used to isolate vacuum from vacuum and vacuum from atmosphere.

They are used to isolate various processes in the fabrication of displays and semiconductor substrates, and are also used to regulate vacuum chamber pressure by placing them between the vacuum chamber and the vacuum pump.

Vacuum valves are used to isolate a vacuum to which heat, gases, or plasma have been added. They must be airtight to isolate the vacuum from the atmosphere without destroying it.

Valve type

KOSLARZE

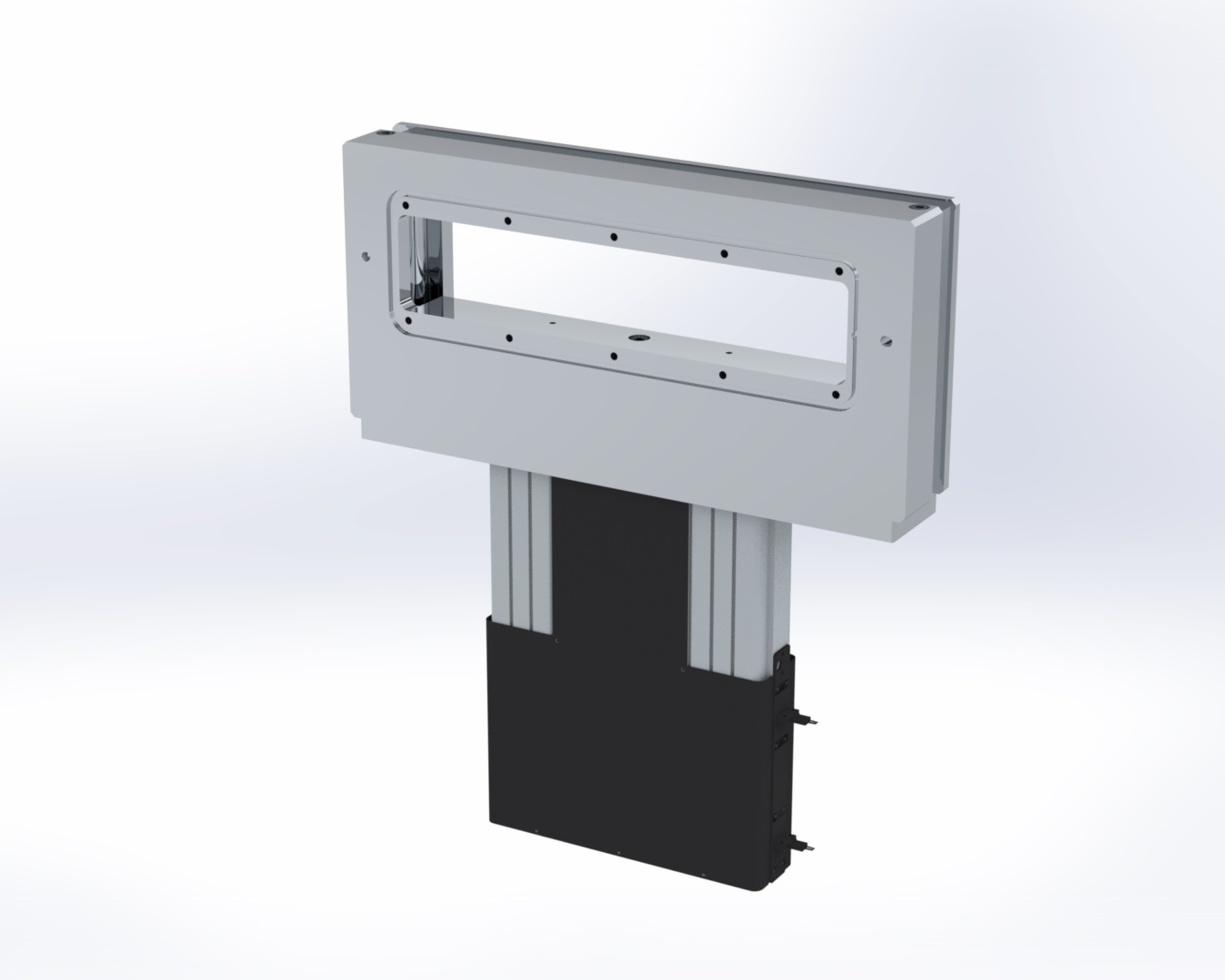

KOSLARZE consists of a case (valve box) with a square opening through which substrates pass, a partition plate (valve plate) to close the opening, and a mechanism (drive unit) to operate the valve plate.

Substrates are placed in the processing chamber and kept in a sealed environment by closing the gate valve, where they are exposed to heat, gases, plasma, etc. for various types of film formation. These processes are mainly performed under vacuum, and the gate valve must have high sealing performance to maintain this environment. KOSLARZE is one of our products.

Features

- After moving the valve plate to the opening position, the valve plate is pressed against the opening seat. The valve plate incorporates an elastic material (O-ring), the repulsive force of which ensures sealing performance. Linear movement to the opening position and tilting movement to seal are performed by an air cylinder via bellows.

- The moving parts are isolated by bellows and there are no metal sliding parts on the vacuum chamber side. There are two types of drive units: one that continuously performs linear and inclined movements using only a cylinder in one direction (KOSLARZE II), and one that performs linear and inclined movements using a cylinder in each direction (NEW KOSLARZE). They are mainly classified by high-speed (KOSLARZE II) and strong sealing (NEW KOSLARZE).

How to use

This is the standard gate valve shape.

There is another type in which the chamber opening is directly sealed by a valve plate (direct mounting).

In this case, there is no valve box as a component. The valve plate is removable with a single bolt for easy maintenance.

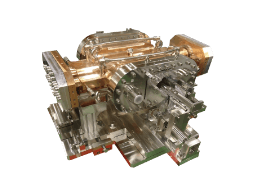

GARIVA

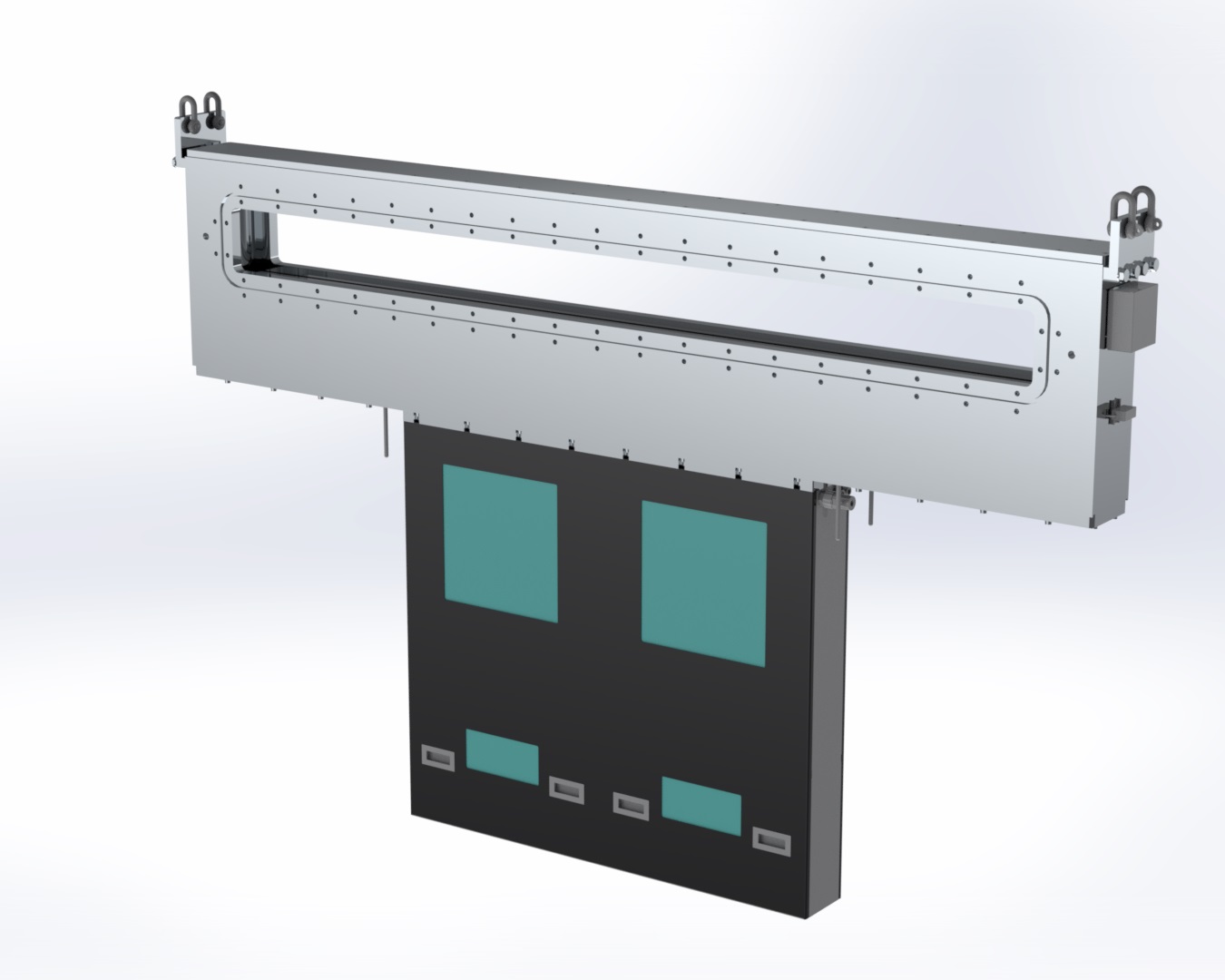

This is a large-aperture gate valve especially designed for ultra-large substrates. Among our products, GARIVA, which employs a differential pressure cancellation mechanism, falls into this category. It is a highly reliable valve with a proven track record of delivery of large valves with an opening size of 3000 mm or more and stable sealing operation.

Features

-

To ensure high sealing performance, the valve plate sealing material must be compressed uniformly even in large openings. To achieve this, the valve plate can be pressed at multiple points by increasing the number of KOSLARZE units, or by installing an air cylinder inside the valve plate to drive the seal at a position very close to the opening (GARIVA).

- The GARIVA, like the MARINA, is equipped with a differential pressure canceling bellows inside the valve plate to significantly reduce the pressure difference acting on the valve plate. GARIVA, on the other hand, has a less rigid and lighter weight drive unit.

How to use

MARINA

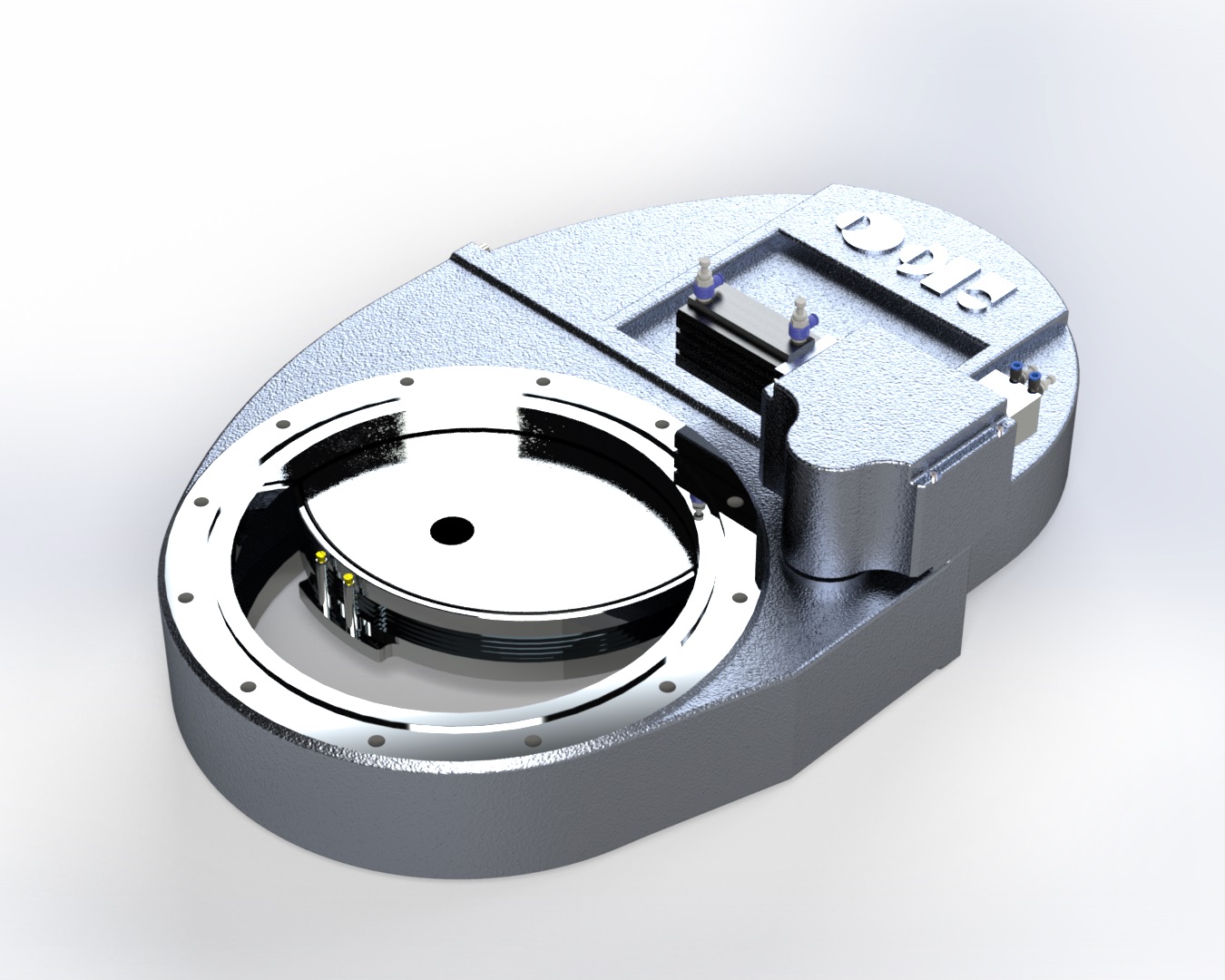

A round pendulum type valve with stable sealing performance, simple structure, and compact design. It is mainly installed between the processing chamber and the vacuum pump as a partition in the exhaust system. Some valves have a function to stop the valve opening at an arbitrary position in order to adjust the chamber pressure (conductance valve).

Like the KOSLARZE, it consists of a valve box, a valve plate, and a drive unit. The opening shape is round for connection to a vacuum pump. MARINA is applicable among our products.

Features

- After moving the valve plate to the opening position, the valve plate is pressed against the opening seat. The valve plate incorporates an elastic material (O-ring) whose repulsive force ensures sealing performance. Rotation to the opening position (like the weight of a pendulum clock) and sealing action are performed by the respective air cylinders via the O-rings.

- The air cylinder mounted inside the valve plate performs the sealing action very close to the opening to ensure stable sealing. When high sealing performance is required to isolate air and vacuum, the pressure difference acting on the valve plate can be significantly reduced by installing a differential pressure canceling bellows inside the valve plate.

How to use

L type Valve (Angle Valve)

L type valves (angle valves) are mainly installed between the chamber and the rougher pump as partitions in the exhaust system.

Currently, only the following models are available.

Goods produced and sold on a continuous basis.

1FLV-25M0 KF25

1FLV-40M0 KF40

1flv-50m0 kf50

2flv-70m0 cf70

1flv-25c0 kf25

1flv-40c0 kf40

1flv-50c3 kf50

2FLV-70C0 CF70

How to use

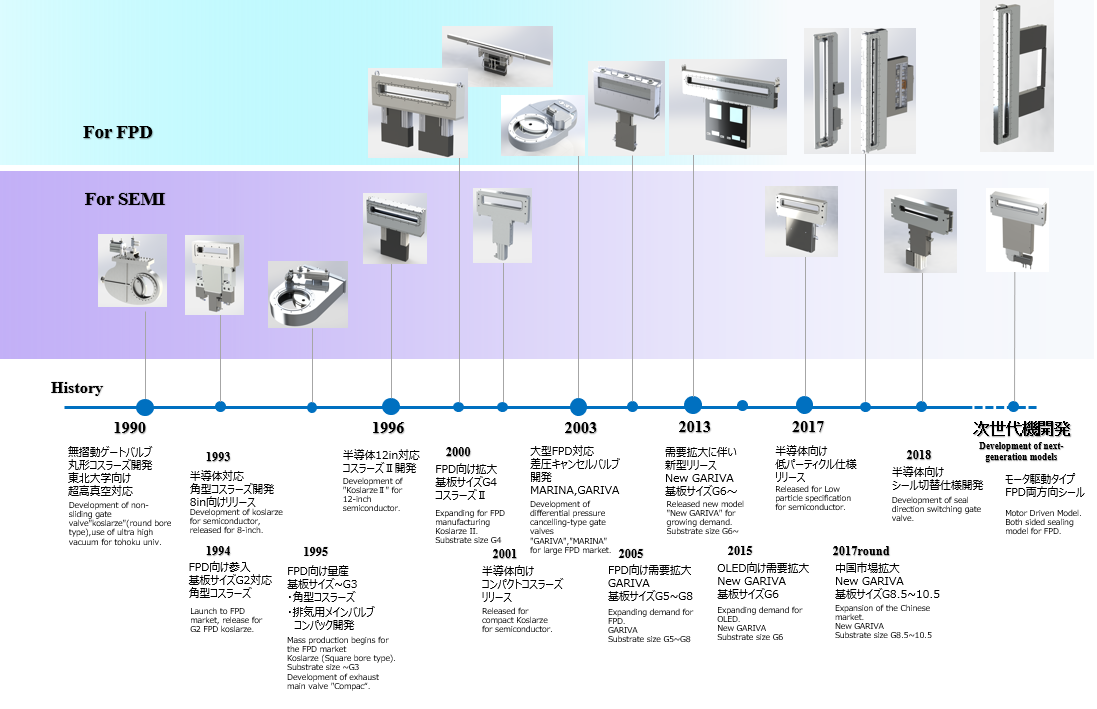

History of Gate Valve Development

Product Information List

Inquiry

For document requests and inquiries,

Please contact us using the email form below or by phone.