- HOME

- HOME

- Company Profile

- Certification (ISO9001, ISO14001)

Certification (ISO9001, ISO14001)

ISO9001・ISO14001

We have unified ISO9001 ・ISO14001 throughout the company.

Through continuous improvement based on the ISO philosophy, we will strive to “improve service quality” to further enhance customer satisfaction.

Basic Policy

Leveraging our expertise in vacuum technology, we strive to contribute to society and enhance global happiness by developing sustainable and environmentally friendly products and technologies.

Our goal is to create unique "vacuum flowers" that are kind to the earth and serve as a bridge to the future.

Quality and Environmental Policy

We are dedicated to delivering the highest quality while minimizing energy consumption, waste, and hazardous substances. Our goal is to provide products and services that support a sustainable future.

2. Path to Becoming a Trusted Company

By valuing customer feedback, addressing issues promptly, and continuously seeking improvement and prevention, we aim to exceed expectations and become a trusted company.

3. Creating the Future through Innovation and Efficiency

We proactively embrace new technologies to enhance operational efficiency and productivity, while also improving quality and reducing environmental impact.

4. Building an Attractive Workplace through Innovation

By offering appropriate training and fostering a corporate culture that encourages creativity, we aim to develop professional talent, boost innovation and competitiveness, and create a pleasant workplace.

5. Building Trust through Legal Compliance and Environmental Protection

We value the trust of our stakeholders and commit to establishing and continuously implementing voluntary regulations regarding legal compliance, the non-use of banned substances, and respect for human rights. We will transparently disclose the results of these efforts to the public.

Scope of Products / Services

- Welded Bellows and Welded Bellows applications

- Molded bellows and molded bellows applications

- Vacuum valves and chambers

- Design and manufacture of vacuum equipment

Organizations Included in the Registered Quality Management System

Head Office:

Hibiya Kokusai Building 414, 2-2-3 Uchisaiwai-cho, Chiyoda-ku, Tokyo

Shikoku Operations: Nakayama Plant, Uchiko Plant:

1580-1, Debuchi 4 Kochi, Nakayama-cho, Iyo-shi, Ehime

Technical Center:

740-5 Shimoakasaka, Kawagoe City, Saitama Prefecture

Osaka Sales Office:

Daido Seimei South Bldg. 1-2-11 Edobori, Nishi-ku, Osaka-shi, Osaka

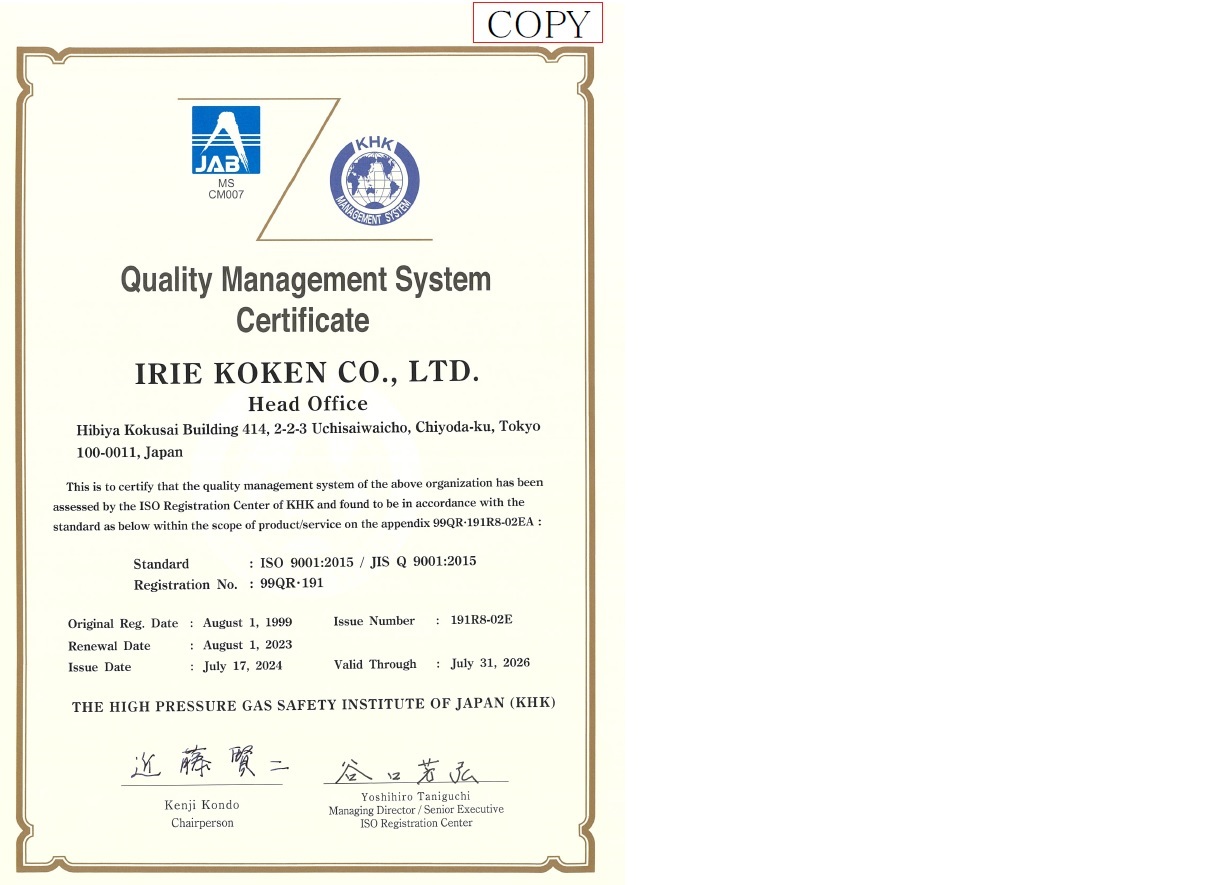

Quality Management System Certificate

- ISO Registration Center, The High Pressure Gas Safety Institute of Japan(KHK)

- Original Reg. Date: August 1,1999

- Renewal Date: August 1,2023

- Valid Through July 31, 2026

- Registration No.:99QR・191

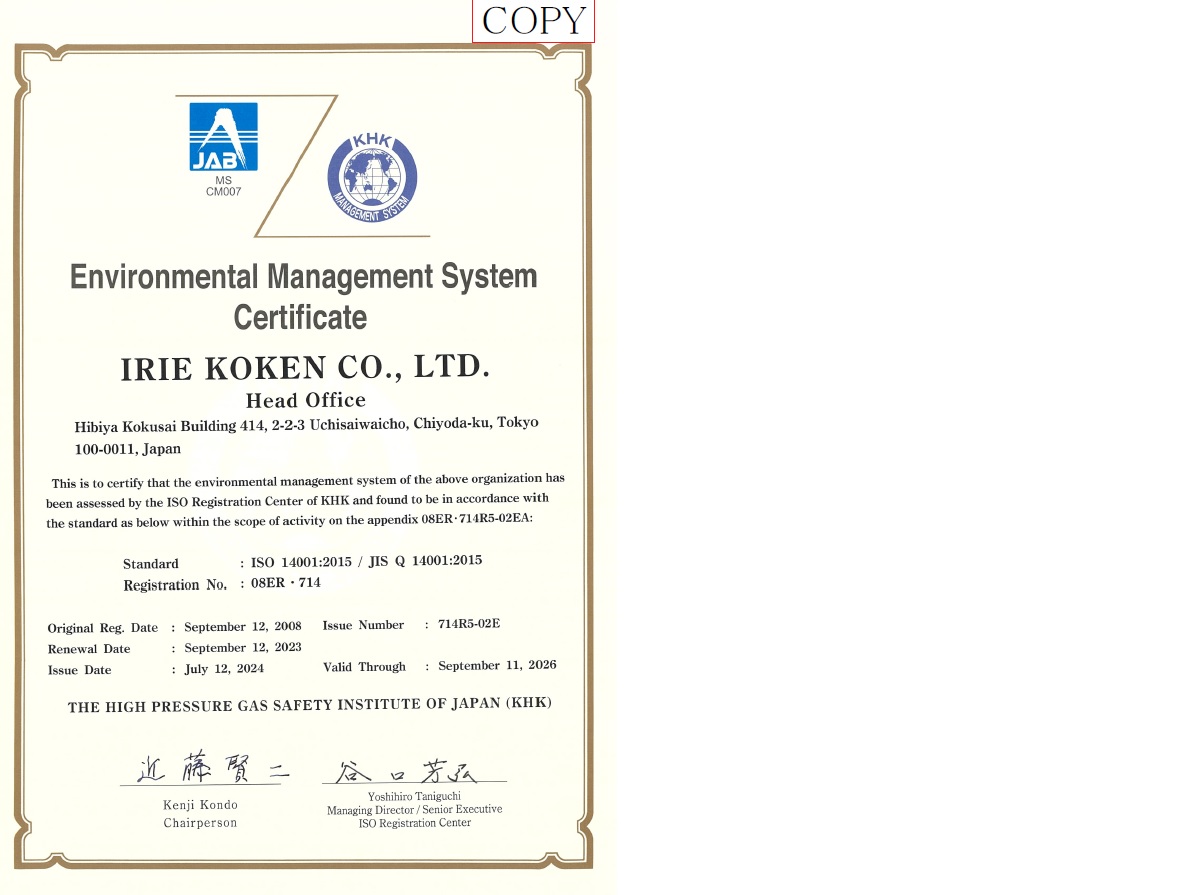

Environmental Management System Certificate

- ISO Registration Center, The High Pressure Gas Safety Institute of Japan (KHK)

- Original Reg. Date: September 12, 2008

- Renewal Date: September 12, 2008

- Valid Through September 11, 2026

- Registration No.:08ER・714

List of Voluntarily Controlled Chemical Substances for Green Procurement and Survey

The following is a list of chemical substances under voluntary control for products, packaging materials, and processes.

Management of Greenhouse Gas Emissions

SCOPE1

SCOPE1 refers to greenhouse gas (GHG) emissions that are directly emitted by companies. This includes emissions from fuel combustion, chemical reactions, and other processes from facilities and vehicles owned or controlled by the company.SCOPE1 emissions are sources of emissions directly associated with the company's activities.

Our FY2023 emissions: 21.4 tons-Co2

Our FY2024 emissions: 19.9 tons-Co2

SCOPE2

SCOPE2 refers to indirect emissions from energy consumed by a company, such as electricity, heat, steam, and cooling. These energies are purchased and used by companies and include greenhouse gas emissions generated in the production process.

Our FY2023 emissions: 604.30 tons-Co2

Our FY2024 emissions: 472.75 tons-Co2

Company Profile List

Inquiry

For document requests and inquiries,

Please contact us using the email form below or by phone.