- HOME

- HOME

- Product Information

- Vacuum Components

Vacuum Components

As a trusted supplier of manufacturing equipment for high-performance semiconductor devices, we provide highly customized vacuum chambers with a one-stop solution—from design to inspection—delivering precision-engineered, high-quality vacuum systems.

Our strength lies in the reliability and expertise that ensure peace of mind for our customers.

Would you like to experience the structure of semiconductor vacuum equipment visually?

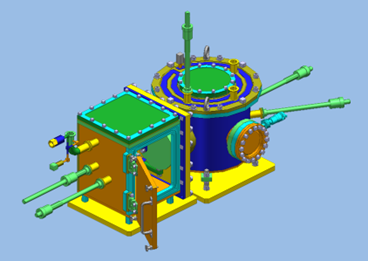

This 3D model features a vacuum chamber integrated with a pass box, enabling clean and efficient sample handling from insertion to processing. In standard operation, samples are placed in the pass box, evacuated to a vacuum state, and then safely transferred into the vacuum chamber by opening the inner door.

Through skeleton views, front/side/top diagrams, and internal structure visualization, this tool allows you to intuitively understand the entire system—almost as if you were interacting with the actual equipment.

Click the link below to explore the design excellence behind our vacuum systems:

https://www.ikc.co.jp/cad/chamber.html

Integrated Manufacturing System

Ensuring Quality for High-Vacuum Equipment—from Design to Inspection

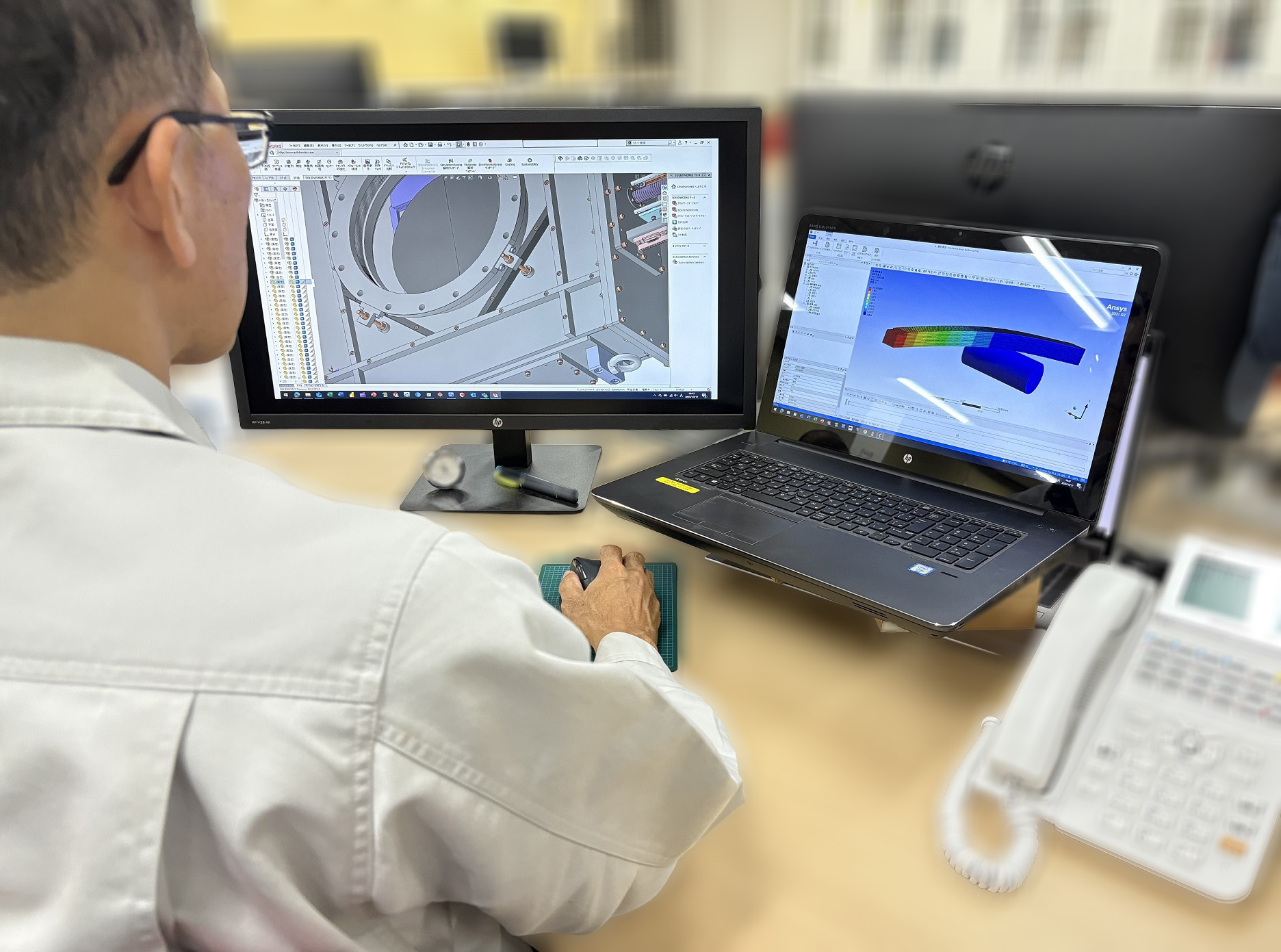

Using advanced CAD software such as SolidWorks and iCAD, we create flexible and precise designs for vacuum chambers. Each 3D model undergoes detailed CAE analysis with ANSYS, evaluating stress distribution, deformation, and thermal behavior under heating conditions. This process optimizes performance and reliability, including scenarios involving cooling systems.

By accurately capturing complex customer specifications, we ensure high precision from the design stage, addressing technical challenges with confidence.

Visual design reviews using 3D models streamline meetings and specification adjustments, enhancing both design quality and communication efficiency to support your development process.

Design

CAM

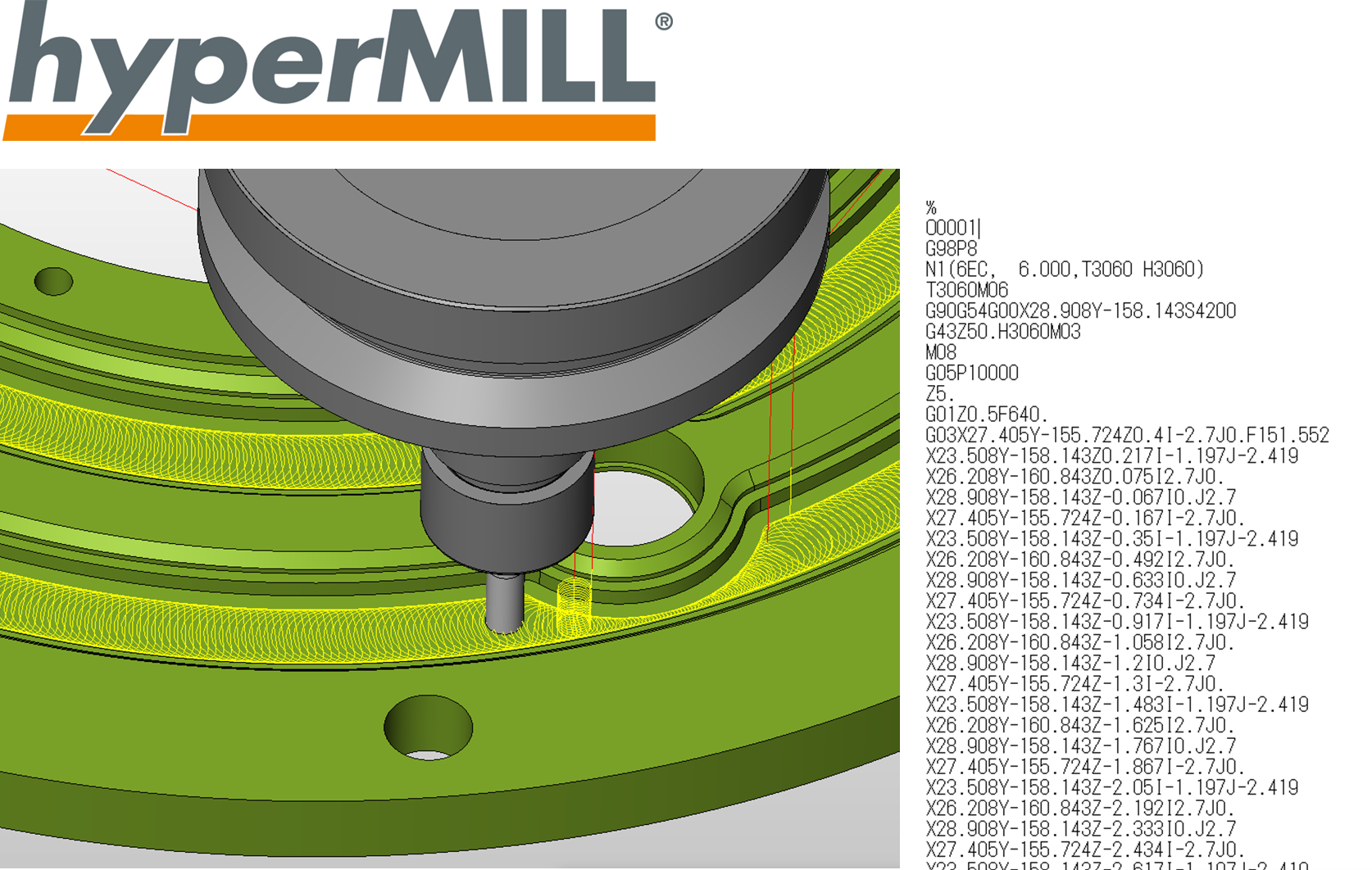

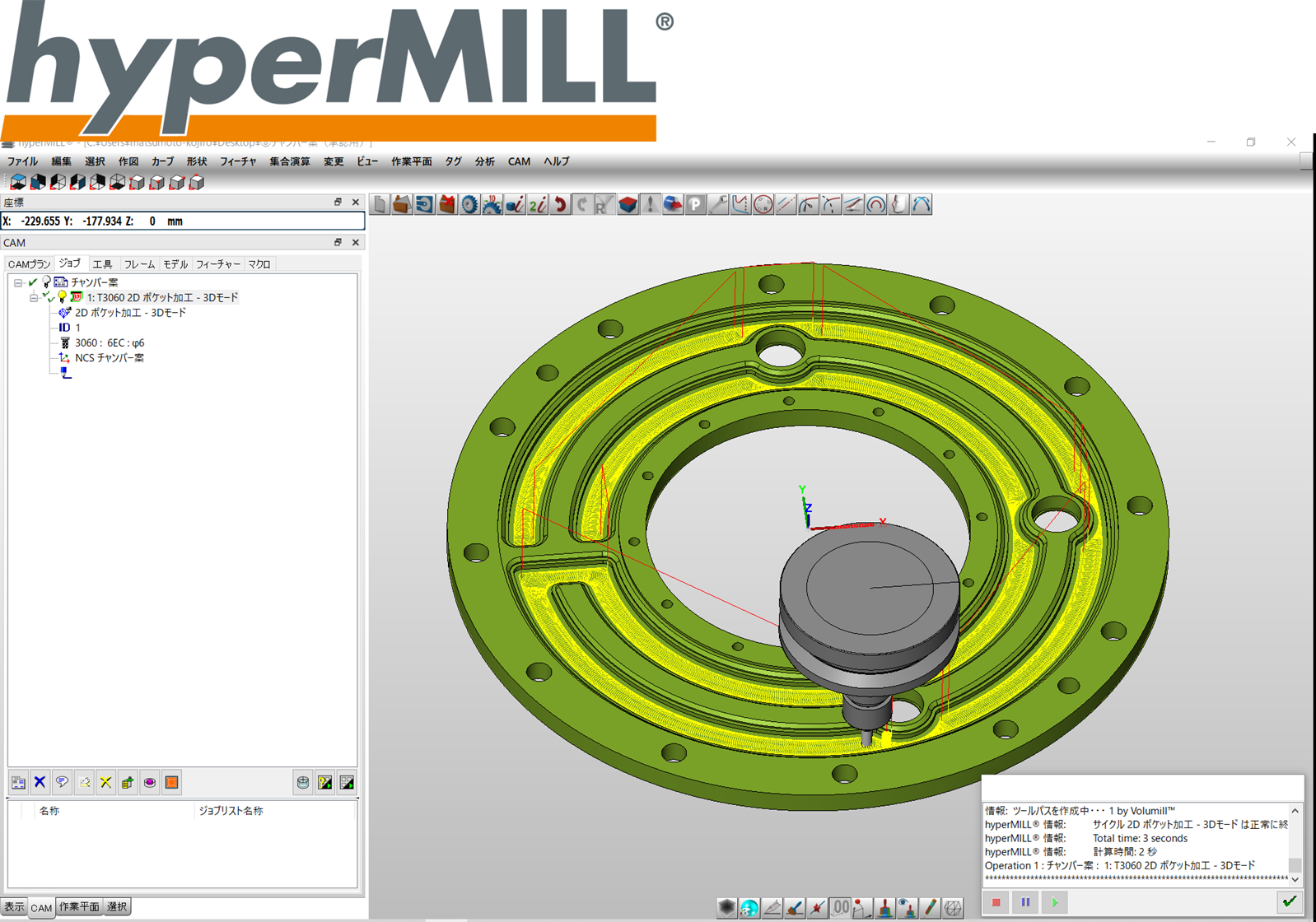

We utilize cutting-edge CAM software such as Mastercam and hyperMILL to convert design data into high-precision machining programs. This enables faithful reproduction of complex geometries and fine structures.

Direct generation of machining data from 3D models improves consistency between design and manufacturing, boosting accuracy and efficiency. For components like vacuum chambers that demand extreme precision, we optimize tool paths and machining conditions to minimize dimensional errors.

Our CAM technology supports multi-axis machining and intricate curved surfaces without compromising design freedom—ensuring both functionality and quality. These capabilities form the core of Irie Koken’s integrated production system, enabling seamless collaboration from design to machining.

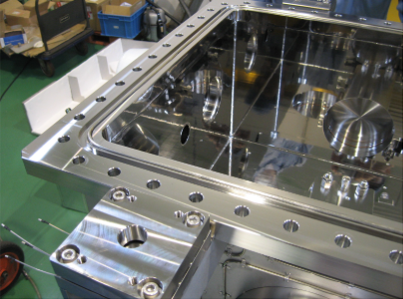

Our facilities include vertical and horizontal machining centers, multi-task CNC lathes, and 5-axis machines, allowing us to select the most suitable process for each product’s shape, material, and precision requirements.

For large vacuum chambers, equipment capability directly impacts quality and lead time. By leveraging 5-axis vertical multi-task lathes, we achieve high-precision machining of complex shapes and multiple surfaces in a single setup—reducing tool changes and re-fixturing, minimizing errors, and improving efficiency.

We also handle simultaneous machining of complex curves and inclined surfaces, supporting high design flexibility and faithfully realizing the designer’s intent. This ensures reliable vacuum equipment that meets stringent semiconductor industry standards.

Machining

Assembly

Experienced engineers perform precise and meticulous assembly based on design drawings.

In the assembly process, we go beyond simply joining parts. We thoroughly verify component alignment and functional performance, ensuring smooth movement of moving parts, airtight sealing, and vacuum integrity. Fine adjustments are made to maximize the overall quality of the finished product.

For high-precision equipment such as vacuum chambers, even the slightest misalignment or assembly error can directly affect performance. To ensure stable quality, we combine the skilled manual work of experienced technicians with verification using precision measuring instruments.

We conduct rigorous quality inspections across multiple stages, including dimensional checks, visual inspections, and leak testing using helium leak tests. These inspections comprehensively evaluate product accuracy, sealing performance, and surface quality—an essential process to ensure the reliability of vacuum equipment.

During dimensional inspection, we use high-precision measuring instruments to verify deviations from design drawings at the micron level, ensuring the alignment and integrity of functional components.

For visual inspection, we carefully check welds, machined surfaces, and the uniformity of surface treatments to enhance the overall quality of the finished product.

In particular, helium leak testing detects minute leaks using helium gas and rigorously evaluates sealing performance under vacuum conditions. For semiconductor manufacturing equipment, where high vacuum retention is essential, a leak-free structure is directly linked to product safety and long-term stable operation.

Through these inspection processes, we have established a system that allows us to deliver high-quality vacuum equipment with performance exactly as designed, giving customers complete confidence. Consistent quality control minimizes product variation and ensures stable supply and reliable manufacturing.

Inspection

Some actual products.

As vacuum equipment, we offer a variety of products according to different customer specifications and applications. We also offer a variety of feedthroughs.

Our products are used in semiconductor manufacturing equipment, FPD manufacturing equipment, solar cell panel manufacturing equipment, OELD manufacturing equipment, glove boxes, physical and chemical experimental equipment, accelerator facilities, and synchrotron radiation facilities.

We also manufacture chambers with special environments such as ultra-high vacuum, plasma environment, and dilute active gas environment inside the vacuum chamber. Gate valves, one of our products, can also be integrated into vacuum chambers for shipment.

Source KEK:This is an example of a vacuum chamber

Types of Vacuum Equipment and Feedthroughs

As vacuum equipment, we offer a variety of products according to different customer specifications and applications. We also offer a variety of feedthroughs.

Linear feedthroughs

Our linear feed throughs are used by our customers for various purposes, such as lowering substrate stages and transferring wafers.

With two types of linear feedthroughs available,

including a bellows seal type and a magnetic seal type with manual and automatic drive systems, IRIE KOKEN offers products that meet various

demands.

Rotary feedthroughs

a vacuum state.

Our rotary feed throughs are used by our customers for various purposes, such as rotating substrates and switching shutters.

With two types of rotary feedthroughs available, including a bellows seal type and a magnetic seal type with manual and automatic drive systems,

IRIE KOKEN offers products that meet various demands.

Multi-operation feedthroughs

In particular, the combination of our MFL series and TSL/TSN series are used by our customers in various fields.(Such as semiconductor manufacturing equipment and accelerator-related facilities)

With two types of multi-operation feedthroughs available, including a bellows seal type and a magnetic seal type with manual and automatic

drive systems, IRIE KOKEN offers products that meet various demands.

Frequently Q&A

What size chambers do you offer?

The maximum production results are as follows

For stainless steel welded construction

Square type: 1500 mm (W) x 1000 mm (D) x 800 mm (H)

Round type: φ1000 x height 800

Various sizes other than the above are also available.

For machined aluminum alloy

Square type: 1500 mm (W) X 1000 mm (D) X 800 mm (H)

Various sizes other than the above are also available.

I am not sure whether to use stainless steel or aluminum. Please let me know if there are any advantages and disadvantages to be aware of.

Stainless steel

Strengths

Durability: Stainless steel is strong and durable. It is suitable for long-term use.

Corrosion resistance: Stainless steel is rustproof and resistant to corrosion.

High temperature resistance: Suitable for use in high temperature environments.

Weldability: Compared to aluminum, stainless steel is easier to weld and can be used for complex structures.

Weaknesses

Weight: Stainless steel is relatively heavy, which is a disadvantage when light weight is required.

Cost: Stainless steel is more expensive than aluminum.

Aluminum

Strengths

Lightweight: Aluminum is lightweight and easy to move and handle.

Cost-effective: Aluminum is relatively inexpensive.

Electrical and thermal conductivity: Aluminum has good electrical and thermal conductivity.

Gas release characteristics: In general, the rate of gas release is lower than that of stainless steel.

However, degassing by high-temperature baking is not possible. Anodized aluminum, which is an anodic oxidation treatment, has a higher gas release rate.

Activation characteristics: Aluminum has lower intensity of induced radioactivity and better attenuation characteristics than stainless steel.

Weaknesses

Low durability: Aluminum is softer and more easily scratched than stainless steel.

Low corrosion resistance: Aluminum is less corrosion resistant than stainless steel.

Which material to choose depends on your specific application and budget.

Stainless steel is better suited when durability and corrosion resistance are important, while aluminum may be a better choice when light weight and cost-effectiveness are desired.

The inside of a vacuum chamber is expected to become hot. What precautions should we take in the event of high temperatures?

Regarding sealing materials, metal seals should be used, or in the case of elastomer O-rings, water cooling is required to keep the temperature below the O-ring's normal heat resistance temperature.

Even in the case of metal seals, it is desirable to control the temperature to be below the typical copper gasket's heat resistance temperature, which is about 400 degrees Celsius.

The chamber body, if made of stainless steel, maintains its mechanical strength up to about 500°C. However, a water-cooled jacket structure should be adopted on the chamber wall in consideration of the above-mentioned sealability issues and safety to the surrounding environment.

Placing several non-contact polished heat shields inside the chamber is also effective in reducing radiation heat transfer.

Related Information

Column

Solution cases

Technical Information

Please take a look at the technical information on bellows.

Inquiry

For document requests and inquiries,

Please contact us using the email form below or by phone.