- HOME

- HOME

- Technical Information

- Whats bellows?

Whats bellows?

“Bellows” is translated as fuigo or jabara in Japanese.

“Fuigo” can be a tool that was used to blow air into kilns by blacksmiths long long ago. While “Jabara” has various meanings, the body of an accordion may come into your head.

In vacuum field, cylindrical objects made of metals and pleated to have expansion/contraction properties, airtightness, and spring properties are generally called “bellows.”

In other words, “bellows” = “expansive pipes.”

What are its applications?

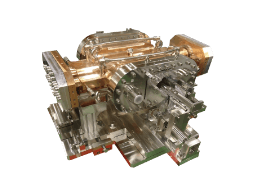

Bellows are not only used for semiconductor, liquid crystal, and vacuum equipment but they are also used as airtight sealing members for gases and fluids across wide range of field, such as accelerators, nuclear fusion, nuclear power, petrochemicals, railways, medicine, and construction.

In particular, a large number of bellows have been adopted as sealing materials for transfer sections where a vacuum is shielded from the atmosphere as well as sealing materials for “complete leak prevention” of vacuum valves and general industrial valves.

Year after year, requirements for special materials and advanced specifications, such as the cleanliness of a bellows surface, upsizing, and long lifetime, are increasing.

Types of Bellows

There are several types of bellows depending on the manufacturing method. IRIE KOKEN offers the following three types.

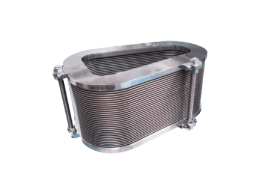

Welded Bellows

Welded bellows are metal bellows manufactured by joining thin-walled metal plates on a precision disc by welding the inner and outer diameters alternately.

Welded bellows can be displaced in axial, perpendicular, and angular directions while the pressure between the inside and outside of the bellows is cut off by welding.

Formed Bellows

Compared to welded bellows, formed bellows have a longer history and various manufacturing methods have been invented. The most widely used methods are roll forming, which is a mechanical forming method, and bulge forming, which is a hydraulic forming method.

We use the hydraulic pressure forming method.

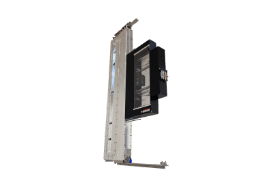

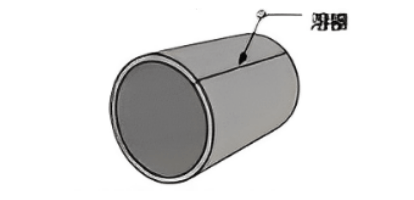

Flexible Tubes

Flexible tubes are relatively small-diameter bellows used for piping equipment that can be bent freely.

We are a manufacturer of stainless steel flexible tubes.

Manufacturing Method and Features

Welded Bellows

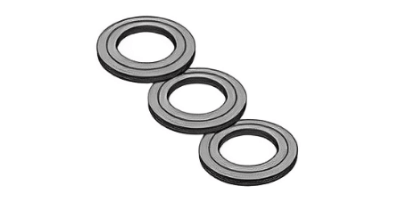

Bellows welds the inner and outer edges of precise thin wave-shaped washer.

- Compact and superior expansion/contraction, and long lifetime designs are available.

- The expansion/contraction properties and spring characteristics can be set by changing the inner/outer diameter dimensions and plate thickness.

- These bellows are highly pressure-resistant.

- Compared with formed bellows, manufacturing costs are high.

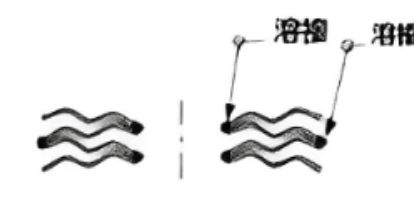

Formed Bellows

Bellows forms under pressure on the inside of metal pipes.

- Although the face-to-face dimension is large, these bellows are best for applications with small amounts of expansion/contraction, having no contacted portions.

- The thread height can be changed freely because they are manufactured by forming work.

- Because of a few maufacturing prcesses, mass-production become possible.

- Compared with welded bellows, manufacturing costs are low.

- Because of the forming work, they can only be manufactured of materials with a relatively large percentage of elongation.

Manufacturing Method

Welded bellows

STEP 01

Material(metal plate)

STEP 02

Corrugated washers are made out of a metal plate

STEP 03

The inner and outer edges are welded

STEP 04

Finished

Formed bellows

STEP 01

Material(metal plate)

STEP 02

The metal plate is rolled up and welded into a pipe

STEP 03

Formed by using jigs

STEP 04

Finished

| Formed beloows | Welded bellows | ||

| Material ※1 |

SUS316L Hastelloy®C-22 A5052 A3004 |

SUS316L Hastelloy®C-22 AM350 equivalent |

|

| Adaptability Comparison ※2 |

Expansion/ contraction properties |

○ | ◎ |

| Pressure resistance |

○ | ◎ | |

| Bendability | ○ | ◎ | |

| Price | ◎ | ○ | |

*1: The materials listed above are materials we commonly handle. For materials other than the above, feel free to ask us.

*2: Based on our comparisons when the same materials are used.

*Hastelloy®C-22 is a registered trademark of Haynes International, Inc.

Representative features of bellows materials

| Corrosion resistance | Heat resistance | Lifetime characteristics | Magnetism | Price | |

| SUS316L | ○ | ○ (500°C or less) |

○ | Non-magnetic | Low |

| AM350 equivalent (welded bellows only) |

× | ○ (450°C or less) |

◎ | Magnetic | Higher than SUS |

| Hastelloy®C-22 | ◎ | ◎ | ○ | Non-magnetic | High |

Product Information List

Inquiry

For document requests and inquiries,

Please contact us using the email form below or by phone.