Big Beam Position Moniter (Big BPM) for J-PARC

Big Beam Position Moniter (Big BPM) for J-PARC

|

Our “FFT Valve” received encouragement prize of “CHO” MONODZUKURI Innovative Parts and Components Award 2013 by MONODZUKURI Nippon Conference and Nikkan Kogyo Shimbun, Ltd. (sponsored by the Ministry of Economy, Trade and Industry, and the Japan Chamber of Commerce and Industry). This prize is awarded to enterprises whose parts play a significant role in support of Japanese industry and society, with the spotlight directed on parts and members playing a behind-the-scenes role as a source of manufacturing competitiveness. The awards ceremony was held at Hilton Tokyo on November 20 (Wed). We are greatly honored to have been selected from among 120 applicants, the largest application pool thus far on the 10th anniversary milestone of the award, and we appreciate that our technological capabilities have been recognized. |

|

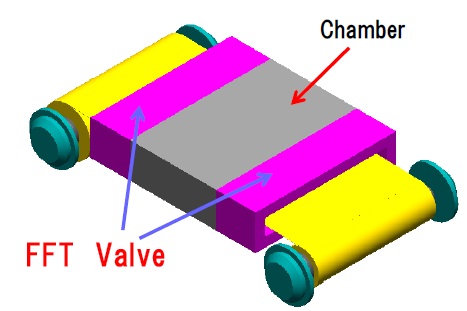

The “FFT_Valve” is a valve that is capable of vacuum deposition equipment for mass production of flexible substrates in film form, etc. We have realized a technology in which rolled film placed under an atmospheric environment or low-vacuum environment is introduced in a high-volume process chamber, and the film is caught at its inlet and outlet to keep the high-volume condition of the process chamber. By including a differential evacuation mechanism inside the “FFT_Valve,” negative pressure that seals the valve body from the high-vacuum side to atmosphere side is also supported. Design of the seal shape and seal material at the film inlet and outlet (partitions) reduce the flutter of the seal that occurs when the “FFT_Valve” is released, with the adhesiveness of the seal material suppressed, while airtightness is increased, so that the film can be fed in smoothly. Since the film take-up section can also be placed in the atmosphere, the vacuum process chamber can be downsized, and also the process chamber can be kept at a high-vacuum even during film roll replacement, facilitating adjustment of the take-up section and roll replacement work, which can contribute to shortening the equipment start-up time after roll replacement. |

|

We will introduce it as a valve for mass production equipment such as for transparent conductive coatings for touch panels (ITO), organic EL lighting, flexible displays, organic thin-film solar cells, etc. |

Inquiry

For document requests and inquiries,

Please contact us using the email form below or by phone.