- HOME

- HOME

- Search by Industry

- Accelerator and Fusion Field

Accelerator and Fusion Field

Synchrotron Radiation, Accelerator, and Fusion Facilities

We have provided various types of equipment to a number of scientific experimental facilities promoted by the government as national projects.

The valuable research results obtained from these facilities have been fed back into a wide variety of products.

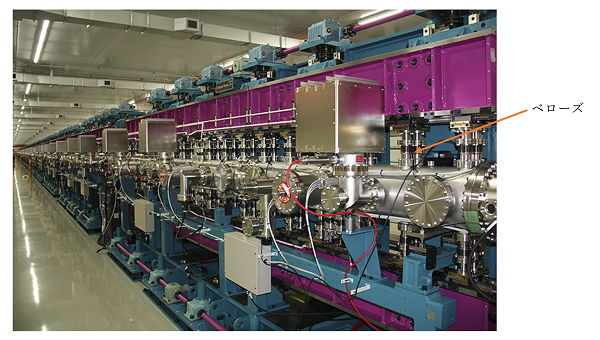

SPring-8/SACLA

|

|

KEKB(Electron-Positron Collider Facility)

|

|

J-PARC(Proton Accelerator Facility)

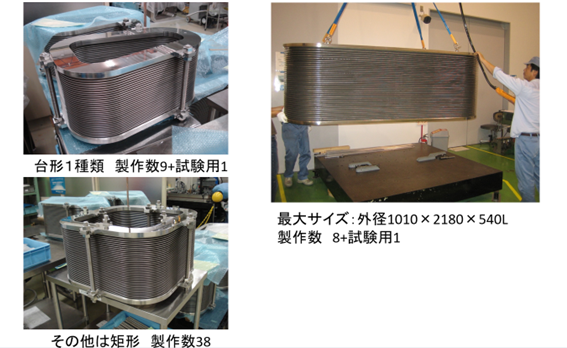

Titanium large formed bellows

(Large beam position detector)

The encouragement prize of “CHO” MONODZUKURI Innovative Parts and Components Award 2010

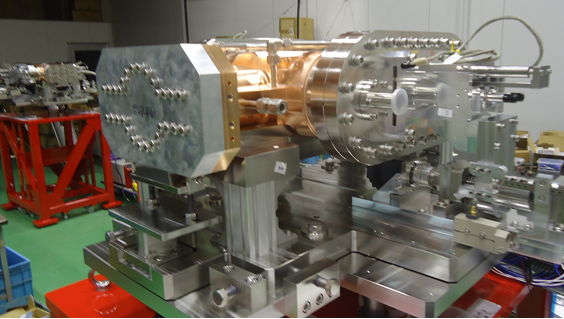

The Big-BPM is a device to detect the position and profile of the proton beam injected into the synchrotron accelerator at J-PARC.

The Big-BPM consists of a rectangular detector body and a circular vacuum vessel with flanges at both ends that covers the outside of the detector body. In order to make the electrode large and rectangular and to reduce pressure effects to zero, the outer casing of the vacuum vessel and the housing that fixes the electrode are separated.

Shielding gas conditions and jigs during titanium welding were studied to develop a welding technique with extremely low oxidation.

Proton Beam Profile Monitor (Driven)

JT60-SA (Fusion Facility)

|

|

Inquiry

For document requests and inquiries,

Please contact us using the email form below or by phone.