Overview

IRIE KOKEN's various types of feeders can be used up to the high vacuum range (some products can be used up to ultra-high vacuum). For the bellows type, highly reliable metal-welded bellows manufactured in-house are used.

IRIE KOKEN is the only bellows manufacturer to offer a range of different types of feeders. As we have a factory in Japan, we can also design and manufacture individual products according to customer requirements.

Types and Features

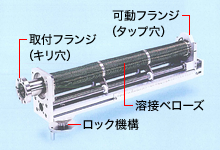

1. Bellows-type linear induction machines

Straight-line induction machines with built-in welded bellows for high reliability and long strokes. Manual and automatic types are available for all sizes.

Built-in welded bellows and standard stroke from 10 to 200 mm.

The welded bellows is used to seal the drive and can be used in the ultra-high vacuum range.

Compact and lightweight, with a simple configuration focused on functionality.

Baking temperatures up to 250°C (manual type).

Automatic type should not be heated.

Compact induction machine Manual induction machine Motor-driven induction machine

2. Bellows-type rotary induction units

High-precision rotary induction units and compact rotary induction units are available for transmitting rotary motion from the atmospheric side to the vacuum side. A metal welded bellows is used to shut off the vacuum and atmosphere, so the unit can be used up to a high vacuum range.

Two types are available: compact rotary induction units with a rotary positioning accuracy (at no load) of 2° ± 0.5° and high-precision rotary induction units with a rotary positioning accuracy of 0.5°.

・Welded bellows seals allow use in high vacuum environments.

・Compact and lightweight with a simple, functional configuration.

・Compatible with baking temperatures up to 120°C (150°C max).

3. Magnetic coupling introduction mechanism

Magnetic coupling insertion mechanism using powerful permanent magnets.

Two types are available: rotary insertion and linear rotary insertion, and can also be motor-driven. Can be used up to ultra-high vacuum areas with pressures of 10-5 Pa or less, and is an extremely durable, highly reliable feedthrough.

・The use of samarium cobalt magnets both inside and outside the vacuum allows for high torque transmission and low lost motion.

・The magnets driven in the vacuum are encased in a thin stainless steel sheet to reduce gas emissions.

・Baking is possible with the magnets installed.

・Semi-permanent by changing the bearings.

・Motor driven, easy to automate and remote control. 4.

4.Hollow linear feeder

This feeder transmits linear motion from the atmospheric side to samples and equipment in a vacuum.

・Hollow design allows optional mounting of driven flanges.

・Welded bellows in sealing area for use in high vacuum environments.

・Bakeout temperature 120°C (max. 150°C).

5. related parts

XY table

For adjusting the axial difference and angle when mounting Magnetically Coupled Linear Feedthroughs (MFL). Ideal for error compensation when mounting equipment in a vacuum vessel.

・Bellows seal mechanism

・Conflat flange range

・The range includes not only XY adjustment but also angle adjustment mechanisms.

6.Shutters

Used to protect viewing ports from deposits and to block light and rays. Shutters are designed for vacuum equipment. Two types are available: manual and automatic (air operated).

・Reliable and proven mechanism using a bellows-type rotary feedthrough.

・Can be used up to the ultra-high vacuum range.

・Butterfly type with wide field of view due to shutter bending mechanism.

・Rotation lock mechanism allows the opening angle to be set as required.

・Double-ended flat flange (double-edged) allows installation in the centre of the pipework.

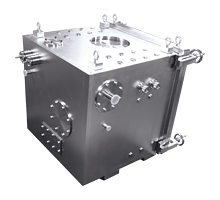

7.Chamber

We manufacture chambers where the chamber interior is exposed to special environments ranging from ultra high vacuum to atmospheric pressure, plasma environments and dilute active gas environments.

・High welding technology enables the handling of complex shapes, including partition valves and girders.