Overview.

IRIE KOKEN has manufactured a large number of inter-chamber shut-off valves (vacuum gate valves) in the vacuum processes required for liquid crystal display (LCD) and semiconductor substrate manufacturing, and is currently expanding the range of applications from small diameters to the large diameters used in TFT and OLED manufacturing.

IRIE KOKEN's vacuum valves are the KOSLARZE series, which uses proprietary technology to maintain a high level of cleanliness inside equipment without slippage.

The GARIVA series features a large bore diameter for ultra-large substrates with a differential pressure cancellation mechanism, while the MARINA round gate valve can be selected from a wide range of products to suit the application.

Types and Features

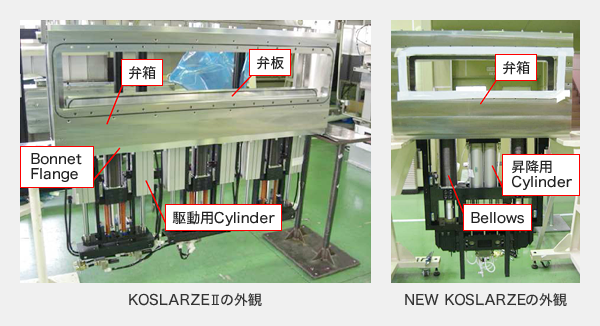

1. Square Gate Valve [KOSLARZE series]

The KOSLARZE II series of rectangular gate valves can perform lifting, lowering and tilting operations continuously by independent cylinder operation, while the NEW KOSLARZE series has excellent sealing properties and uses a dedicated cylinder for opening, closing and tilting operations respectively.

・IRIE KOKEN's unique technology ensures a high level of cleanliness inside the machine without slippage.

・High sealing performance and stable performance against back pressure sealing.

・Designed for easy maintenance.

・Designed for easy maintenance. - Stable quality with a service life of 1 million cycles.

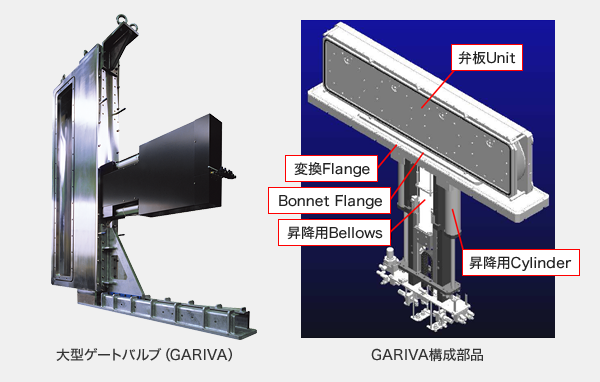

2. Large Gate Valve [GARIVA]

This is a large-aperture gate valve specially designed for ultra-large substrates, and is a highly reliable valve with stable sealing operation, proven in the supply of large valves with an aperture size of 3000 mm or more. A differential pressure cancellation mechanism within the valve plate allows the pressure difference acting on the valve plate at the time of back pressure to be significantly reduced, thereby reducing the rigidity and weight of the valve plate and drive unit.

・Adopts a differential pressure cancellation mechanism (significantly reduces the differential pressure acting on the valve plate).

・Easy to increase the size of the sealing orifice (proven in a wide range of applications from G5 to G10).

・Lightweight (compact mechanism on the atmospheric side).

・Reduced air consumption (50% less than our conventional products).

・Easy maintenance (valve plates can be easily removed).

3. round gate valve [MARINA]

A round pendulum type valve with stable sealing performance, simple structure and compact design. It is mainly installed between the processing chamber and the vacuum pump as a partition in the exhaust system. Models are also available with a function to stop the valve opening at any position to adjust the chamber pressure.

Arrangement.

・The differential pressure cancellation mechanism (which significantly reduces the differential pressure acting on the valve plate) ensures stable sealing performance even in the event of reverse pressure sealing.

・The size of the sealing orifice can be easily increased.

・The valve plug unit can be easily removed and the O-ring easily replaced by means of a maintenance cover.