Overview

The source of IRIE KOKEN's technology lies in the manufacture of metal bellows. IRIE KOKEN places particular emphasis on the field of precision bellows, which require high performance and reliability and are used in many air-tight fields.

The main characteristics of IRIE KOKEN's metal bellows are "elasticity", "airtightness" and "resilience", and by combining these characteristics, they support many manufacturing sites as expansion joints for piping. In particular, their excellent air tightness is used in a wide range of fields, from the vacuum area of semiconductor and liquid crystal manufacturing equipment to accelerators, nuclear fusion, nuclear power, petrochemical, railway, medical, construction and space, and they are constantly evolving towards a contamination-free environment.

Types and Features

1. welded bellows

Metal bellows are manufactured by joining thin-walled metal plates to precision discs by hermetically welding the inner and outer diameters alternately. The bellows can be displaced in the axial, vertical and angular directions while the internal and external pressures are cut off by welding.

・Bellows of any size and material can be made to order, as long as they are made from weldable metal.

・The high degree of freedom in the dimensions of the inner and outer diameters means that elasticity and spring characteristics can be freely adjusted.

・The high dimensional accuracy makes it easy to predict properties such as spring constants and service life.

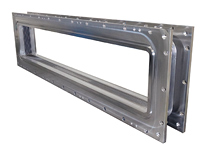

Large welded Rectangular bellows

Rectangular bellows, a lower cost version of conventional rectangular bellows, but with the flexibility to absorb faults and sufficient strength, designed for thorough optimisation and compatibility with equipment devices, with particular attention to the metal material.

Both weight and cost have been successfully reduced by 35%.

2. Formed Bellows (general)

IRIE KOKEN's moulded bellows are manufactured using a unique hydraulic moulding process with a clean appearance and excellent strength. They combine flexible expansion, contraction and bending characteristics with airtightness, and demonstrate their strength in vacuum and other harsh manufacturing environments.

・Flexible response to mountain heights through the forming process.

・Fewer production steps mean that dedicated machinery can be used for high volume production, ensuring consistency of quality.

・Production costs are lower compared to welded bellows.

3 Formed bellows (flexible tubes)

These are bellows of relatively small diameter, intended for piping of equipment that can be freely bent. IRIE KOKEN manufactures stainless steel flexible tubes with excellent air tightness and cost balance as standard specifications for vacuum piping connections.。

・Flexible bending and easy tube connection.

・Flexibility for customisation as tube lengths can be easily adjusted.

・Low deformation under pressure and light weight for easy bending.