Do you have any of these problems at your design site?

After designing, it is found that there is a part buffer or dimension difference, and most of the parts have to be redesigned.

It is time-consuming to create 3D data of standard parts, and time cannot be spent on the main design...

There is no engineer in the company who can visualize and design a finished product from 2D data.

Why IRIE KOKEN provides data?

As an engineering company, Irie Engineering wants its engineers to focus on the development and design of its main products. For this reason, we have created and started providing 3D data for welded bellows, valves, piping components, etc. We hope you will make use of this data.

Three advantages of utilizing the data

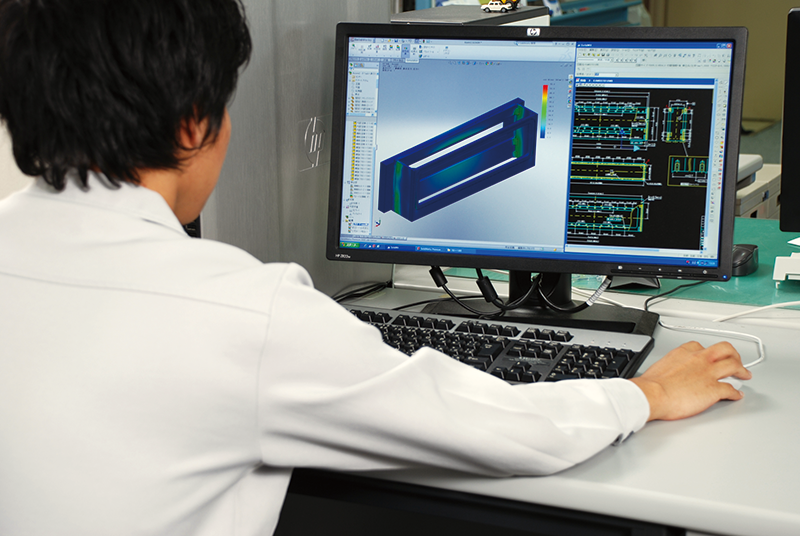

Advantage 1: Significant time and cost savings

By utilizing the data, interference checks can be performed in advance after the parts are assembled. This eliminates re-design and rework in subsequent processes, contributing to significant time and cost savings.

Advantage 2: Reduces the workload of valuable engineers

By utilizing the data, the need to convert purchased standard parts to 3D is eliminated, allowing engineers to focus on key design developments. Valuable human resources can be maximized and more time can be spent on improving quality.

Advantage 3: Standardize technical differences within the company

Compared to 2D data, 3D data makes it easier to understand the finished product image and reduces differences in design efficiency due to skill and experience.

CAD Data

User registration is required to download SDS. Please click on “Go to Detail Page” to proceed; if you have an ID and password, please click the “Login” button; if you do not have an ID and password, please login after user registration.